- Home

- Automation of technological processes

- Equipment

- Control and measuring devices

- Flow measurement devices

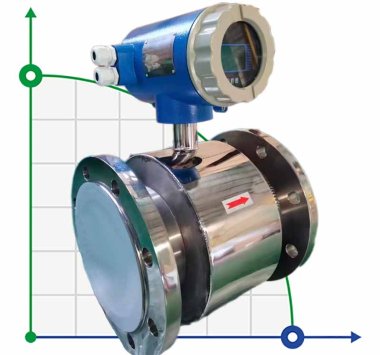

Electromagnetic flow meter

Electromagnetic flow meter

- Medium: conductive liquids and suspensions, etc.

- Accuracy: ±0.5%

- Measuring range: 0.06 – 18000 m3/year.

- Contents of the displayed information: instantaneous flow, accumulated flow.

- Measuring gauge: DN 15-DN3000.

- Connection type: threaded and flanged, plug-in, etc.

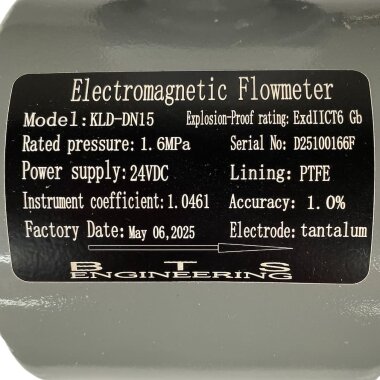

- Power supply: lithium battery or 24V DC power supply, 220V AC power supply.

- Output: 4-20 mA output, RS-485 and GPRS COMMUNICATION, Hart, etc.

- Advantages: high accuracy, wide measurement range, ease of operation.

Description:

Intelligent electromagnetic flow meter for measuring volumetric flow in closed pipelines producing liquids and slurries, such as pure water, wastewater, various chemical salt solutions, mud slurries, pulp, pulp and liquid products, etc. The measurement principle of the smart electromagnetic flow meter is based on Faraday's law of electromagnetic induction: when the leading fluid cuts off the magnetic force in the magnetic field and generates an induced electric potential in the conductor. The flowing electrically conductive liquid induces a speed proportional to the average voltage, which induces a voltage signal by directly contacting the liquid with two or more detection electrodes, and is sent through the cable converter by intelligent processing. The measurement then appears on the LCD or converted into a standard 4~20mA signal and 0~1KHz output signal.

The correct choice of installation location and correct installation of the flow meter are very important links. If an error is made during the installation process, it will directly affect the measurement accuracy. It will also affect the service life of the flow meter. It may even damage the flow meter. When choosing an installation location, pay special attention to:

- The axis of the measuring electrode should be approximately horizontal.

- The measuring tube must be completely filled with liquid.

- The pipeline must be at least 5xD in length in front of the flow meter (D is the internal diameter of the straight pipe flow meter). The rear part must have a straight pipe length of at least 3xD (D is the internal diameter of the flow meter). All installation requirements are specified in the instructions supplied with the device.

Selecting Tools - very important work. Please pay special attention

1. Data collection

- Name of the measured liquid;

- Maximum flow, minimum flow;

- Maximum working pressure;

- Maximum temperature. Minimum temperature.

2. The measured liquid must have a certain degree of conductivity, conductivity >5 nS/cm.

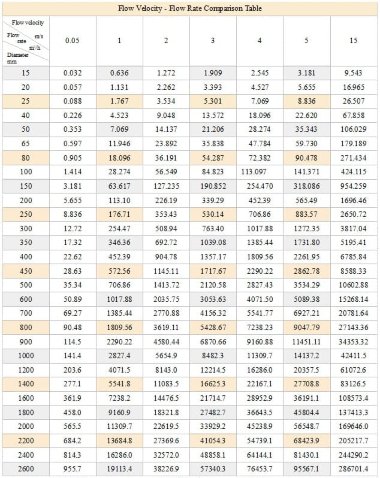

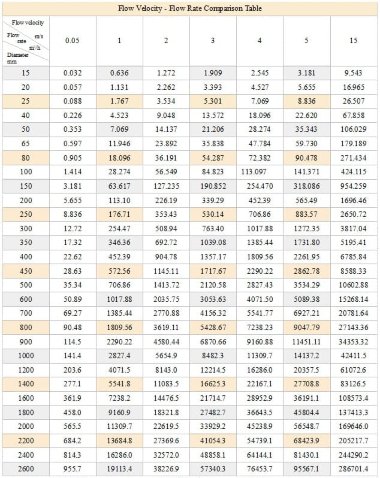

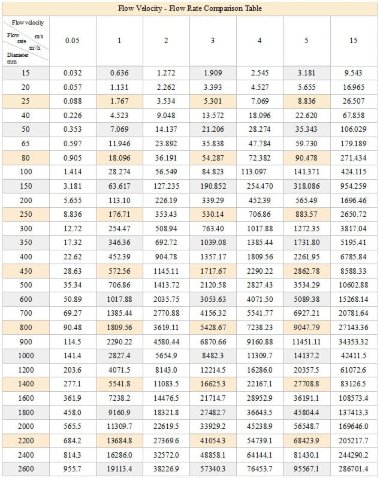

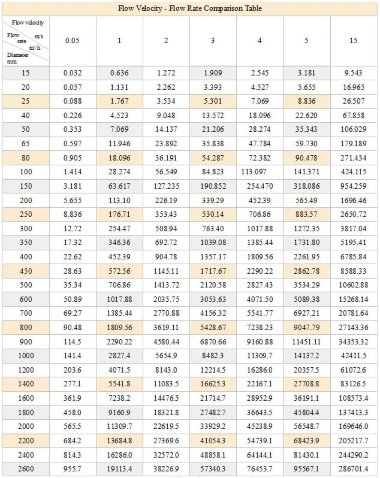

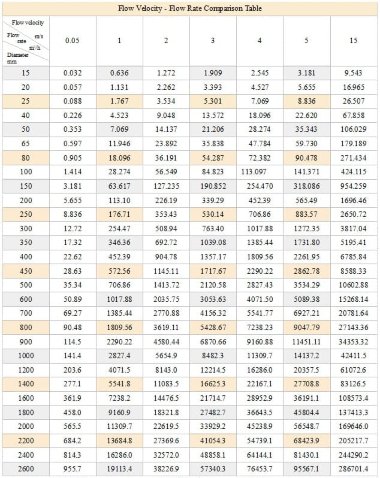

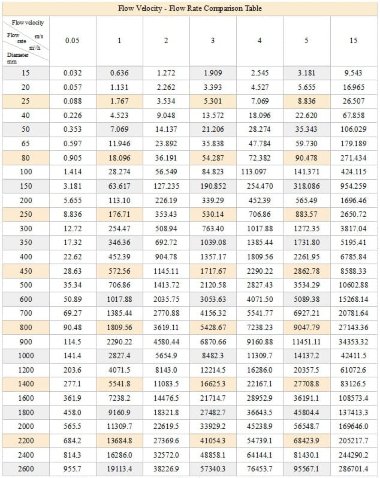

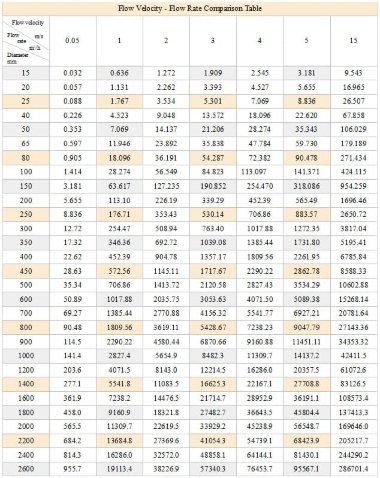

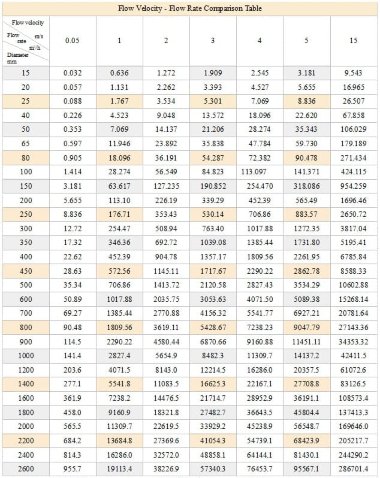

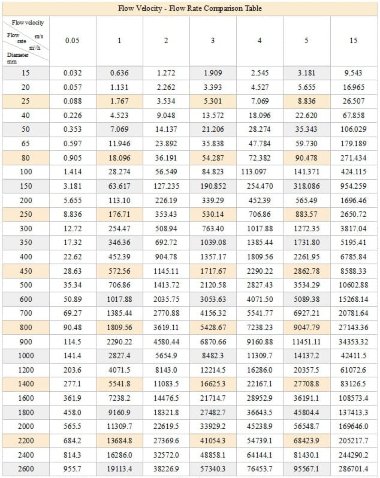

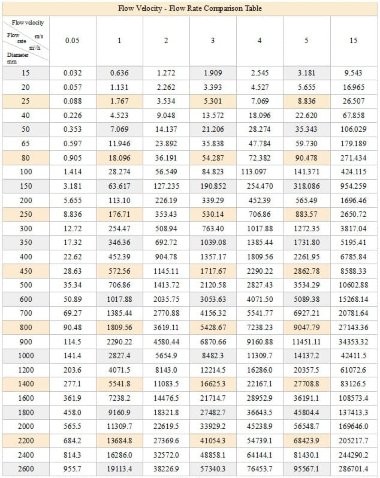

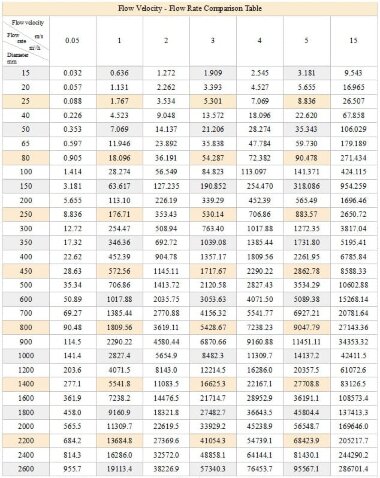

3. The maximum and minimum flow rates should be as shown in the table below:

4. The actual maximum working pressure should be less than the rated working pressure by one meter.

5. The maximum operating temperature and minimum operating temperature must meet the temperature requirements of the flowmeter.

6. Determine the presence of negative pressure (vacuum).