Pipeline valve

Shut-off and regulating pipeline fittings

Pipeline fittings a device installed on pipelines and intended for controlling (disconnecting, distributing, regulating, dumping, mixing, phase separation) flows of working media (liquid, gaseous, gas-liquid, powdery, suspension, etc.) by changing the area of the passage section.

To control flows in pipeline structures and systems, specialized fittings are used, which allow to turn off, distribute, regulate and mix, correcting the cross-sectional area.

The shut-off and regulating valve, changing the flow rate of the transported substance, blocks or distributes its flow, regulating various parameters: pressure, pressure or temperature. It can be mounted on pipelines, tanks and other units.

The functional purpose of pipeline fittings allows dividing it into the following types:

- Locking It ensures complete coverage of the flow in the pipes. It is in the greatest demand and occupies more than 80% of the market.

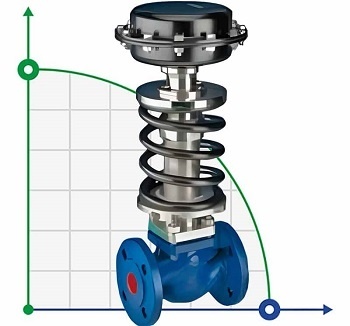

- Regulating. Maintains the necessary values of certain parameters, controlling the flow rate of the working medium. Temperature, pressure, composition and concentration of substances can be changed with the use of this type of fittings. It is worth highlighting the throttle fitting related to the regulating valve. It is used in cases where it is necessary to significantly reduce the compression of the transported substance. It works successfully with significant pressure jumps.

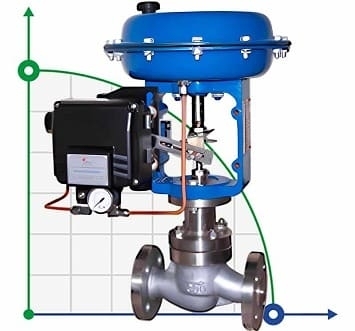

- The shut-off and regulating valve combines the functions of overlapping and flow control.

- The emergency shut-off system excludes the factor of negative influence on the pipeline if the pressure or direction of the transported medium exceeded the permissible values by covering the protected section from the rest of the system.

- Protective In an emergency situation, it opens to dispose of the excess amount of the transported substance from the structure.

- Mixing, the function of which is to control the flow of the working medium to distribute it in a certain direction or for mixing. It is most often used in heating systems to obtain the optimal temperature.

- Phazorazdelytelnaya - automatically distinguishes working environments depending on their phases and states.

High-quality shut-off, regulating and safety fittings that allow you to control the transported working medium: water, steam, gas, oil and other aggressive liquids are a guarantee of the strength and reliability of modern communications.

Pipeline stop valves can be made of the following materials:

- steel;

- brass;

- bronze;

- cast iron.

The main characteristics of such elements are: the diameter of the pipe that can be connected, and the maximum excess pressure when the temperature of the medium in the pipeline is 20 degrees. The choice depends on the technical conditions of the pipeline in which it will be used. Gas pipelines, water mains and systems for pumping aggressive substances use different types of equipment.

Types of shut-off fittings

There are various types of shut-off valves:

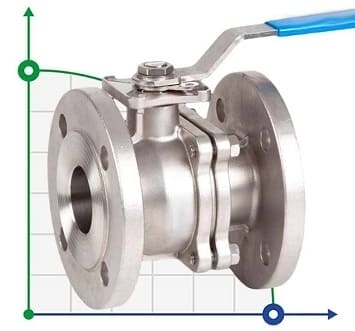

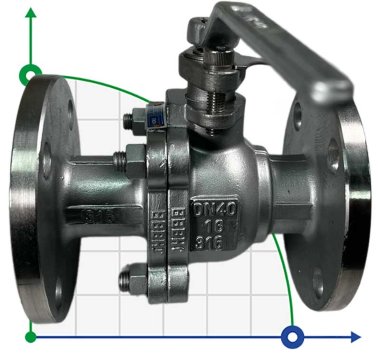

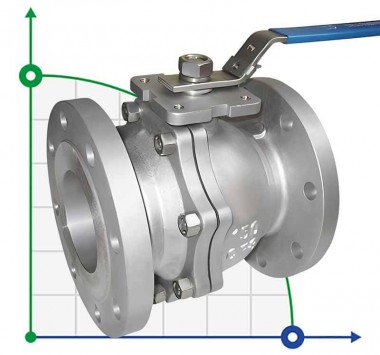

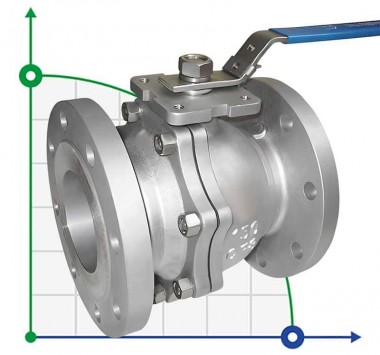

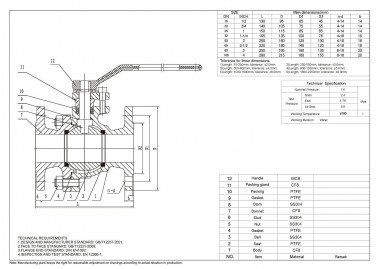

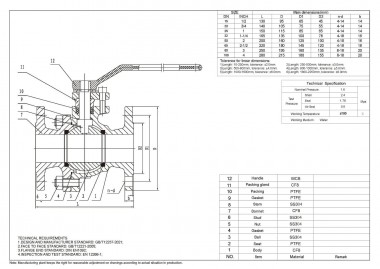

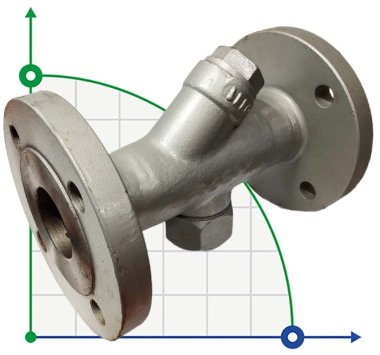

1. Shut-off valves are present on all pipelines. They are connected to the pipe by a flange or coupling connection. Taking into account the working environment, the cranes are divided into ball and cork cranes.

Gland couplings are plug valves with a rubber or hemp gland inside, cast from cast iron for use in water and oil pipelines. The temperature of the transported substance should not exceed 100 degrees. The faucet can be installed in any position.

Cork couplings - cast iron for gas pipelines. The maximum temperature threshold is 50 degrees. They are also easy to install.

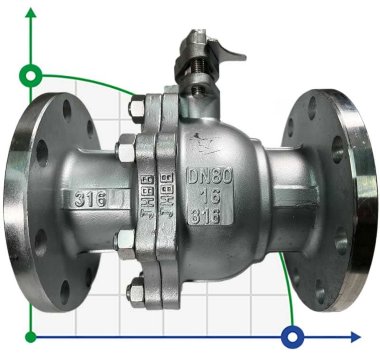

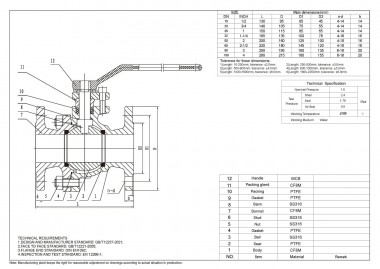

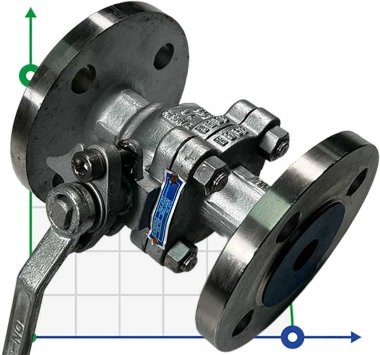

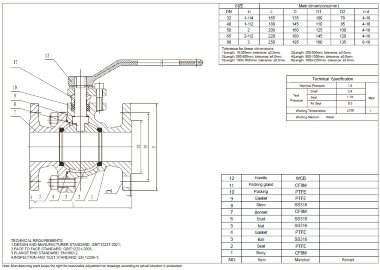

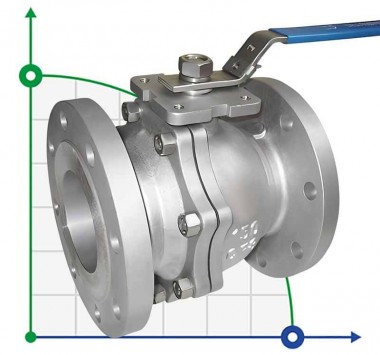

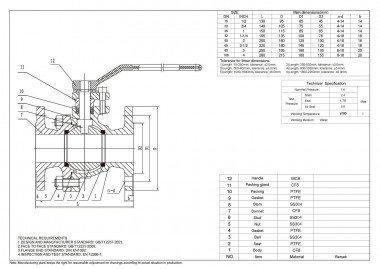

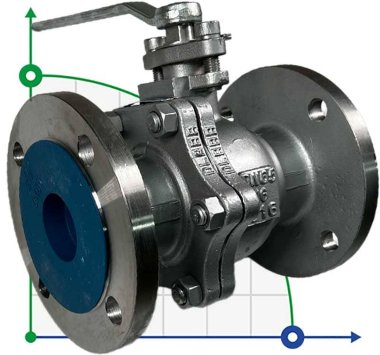

Flanged ball valves are produced in steel (temperature range 30-70 degrees) and cast iron, which can withstand a 100-degree load.

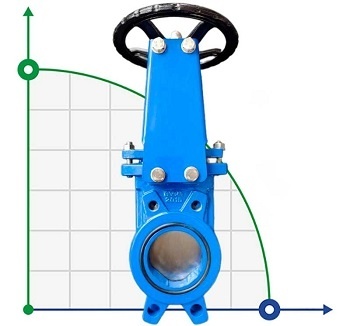

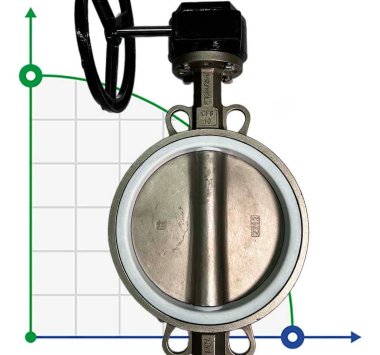

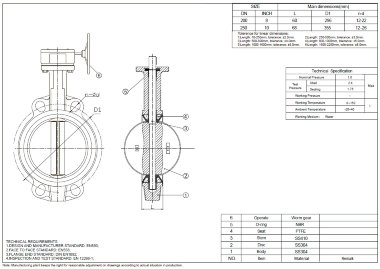

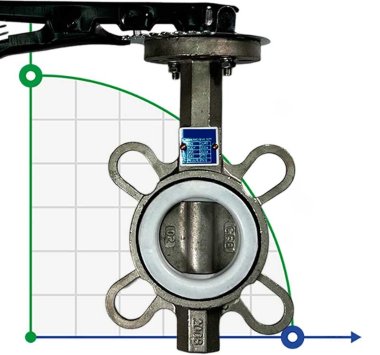

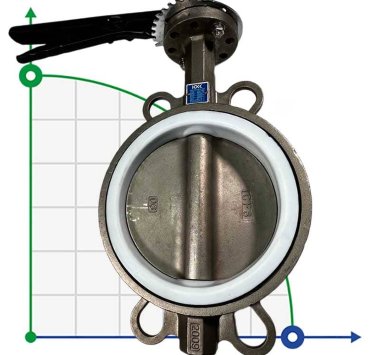

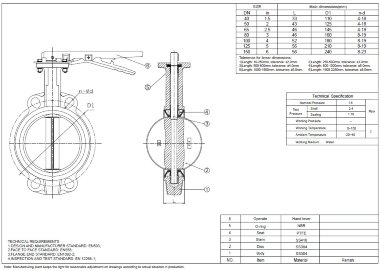

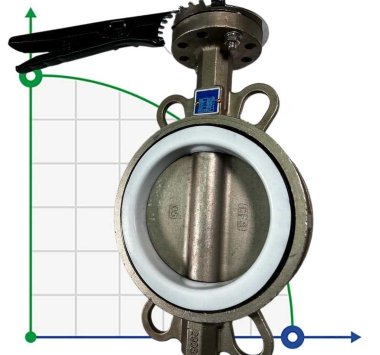

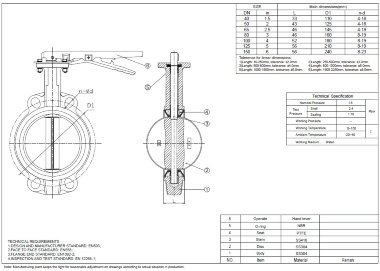

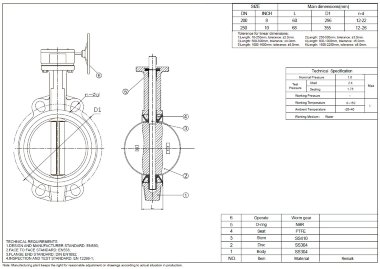

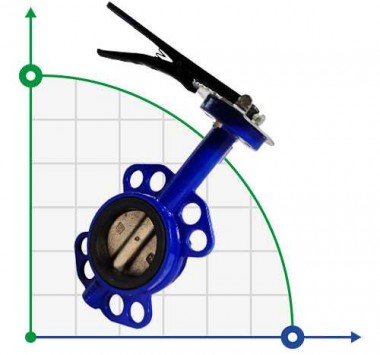

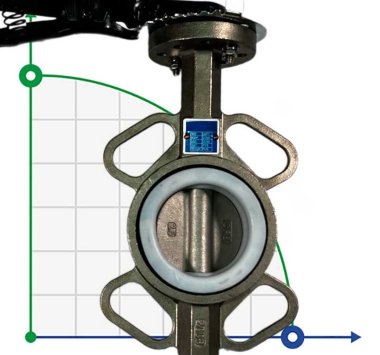

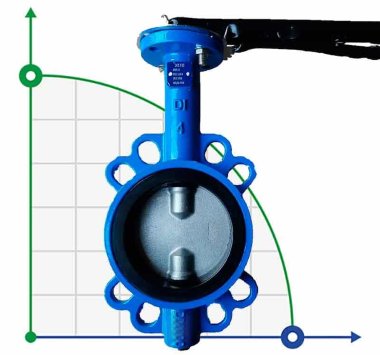

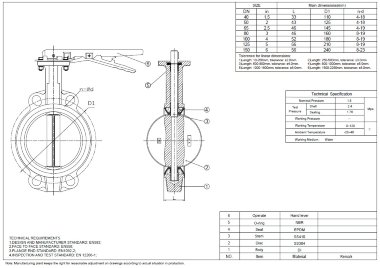

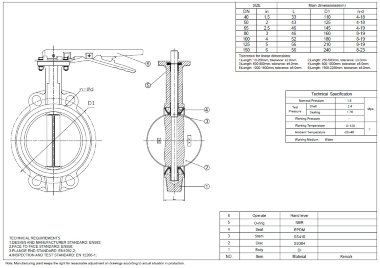

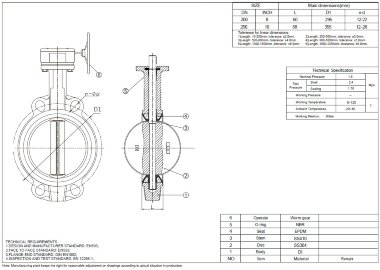

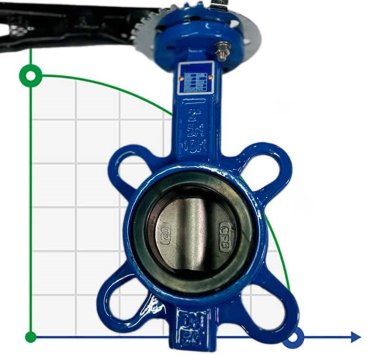

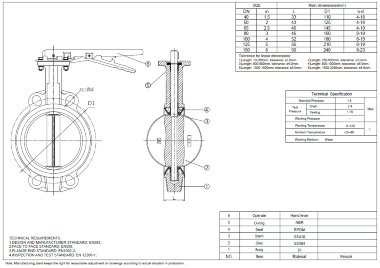

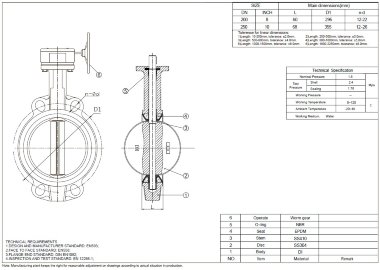

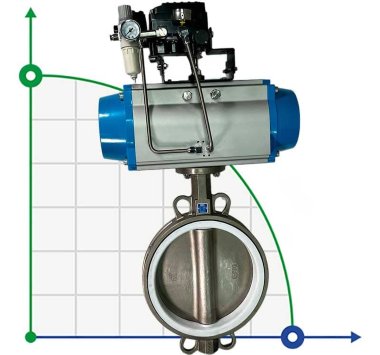

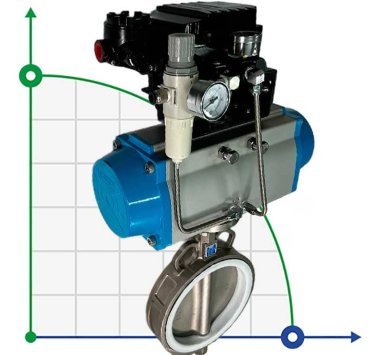

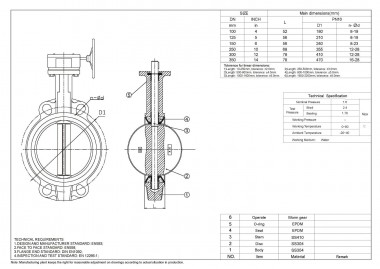

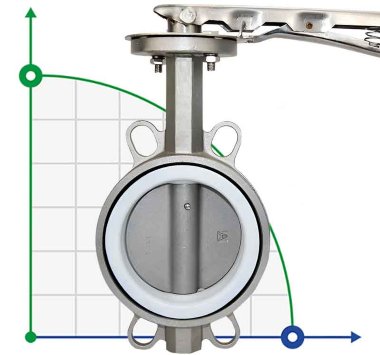

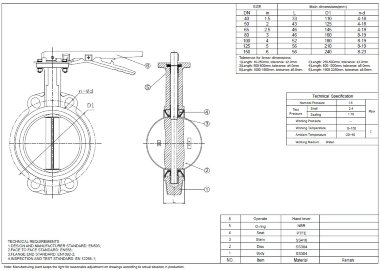

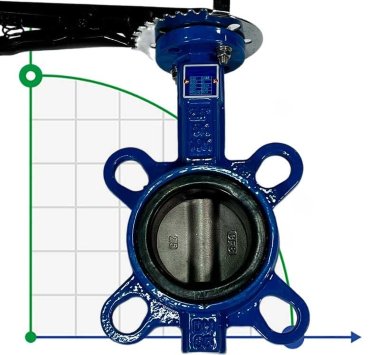

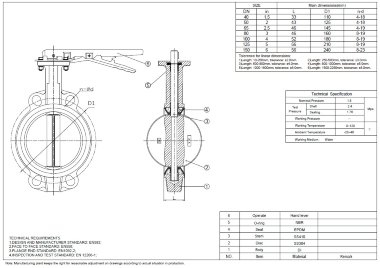

2. The shut-off valve is made in the form of a disk rotating around its axis, located perpendicularly or at a certain angle to the direction of movement of the substance. They are mainly mounted on large-diameter pipelines with low pressure of the working medium. They are installed hydraulically or electrically, as well as manually cut into the pipeline using welding or flange connection. The body is made of cast iron, and the disk is made of steel. They are suitable for use in acidic and alkaline environments and do not require maintenance.

3. Pipe valves periodically block the flow of the working medium. When they are equipped with an electric drive, it becomes possible to control them remotely. They are made of cast iron, steel, stainless steel or alloys of non-ferrous metals. The choice of material from which the shut-off device will be made depends on whether the alkaline or acidic medium will be transported through the pipeline.

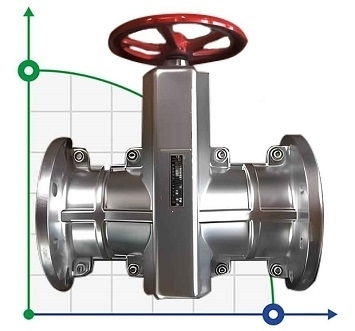

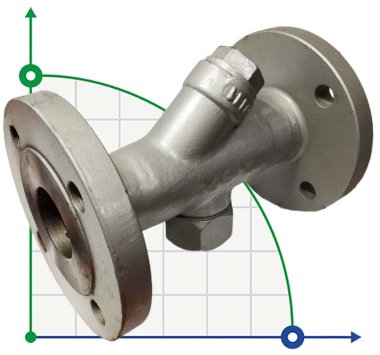

4. The shut-off valve is designed to completely shut off the flow. With its help, it is impossible to regulate the working pressure. The valve should always be fully open or closed. The spool and spindle that make up the system block the flow parallel to its direction to prevent water hammer. Valves for high-pressure systems are welded to thick-walled pipes. It is also possible to connect with flanged pipes and couplings. The latter is common in pipelines for transporting water and air.