Commercial offer

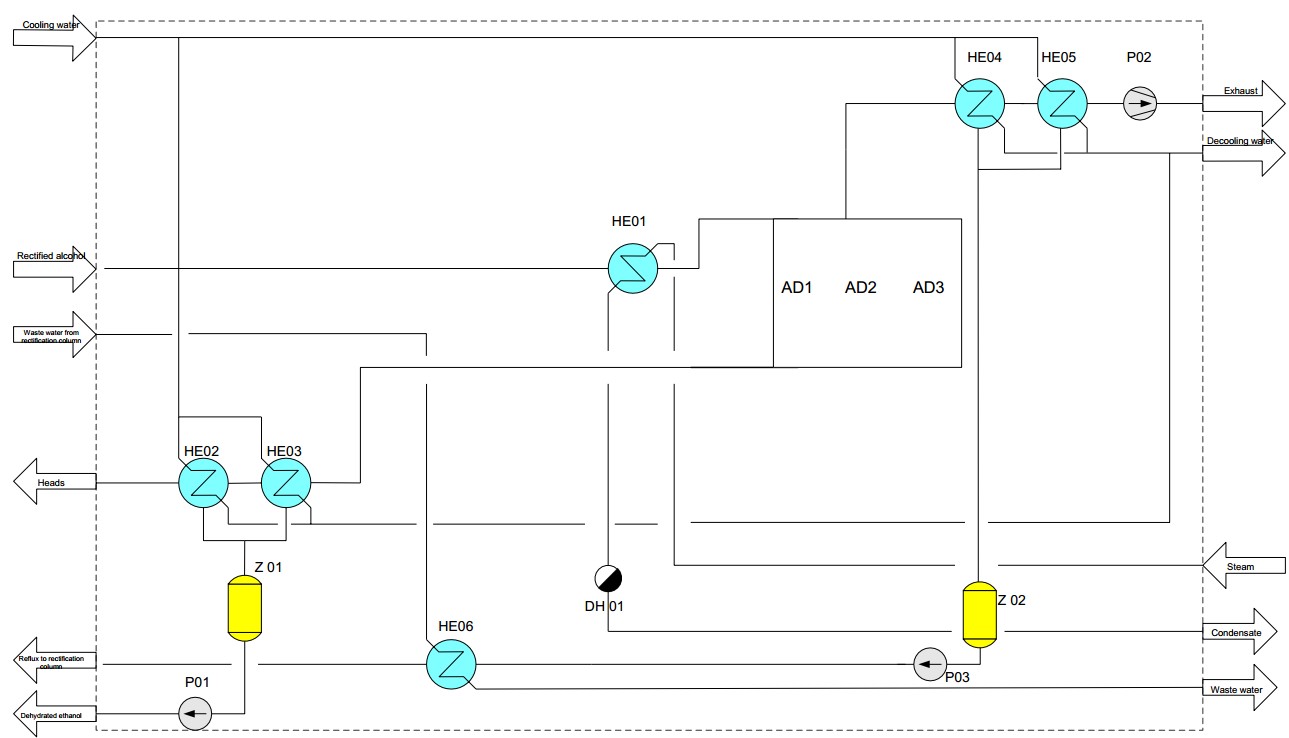

This proposal concerns the construction of a facility (assembly line) for the production of anhydrous ethanol. The developed installation is modern, economical and fully automated. Low power consumption (0.1 kg of sharp steam / DM3 absolute ethanol (depending on the quality and strength of rectified ethanol). It is assumed that the concentration of rectified ethanol is the same as 96% by volume. and its pressure is about 2.2 bar abs. (at the top of the column). In addition, the impurity content must meet the requirements of the standard for the quality of rectified ethanol. Rectified ethanol with the above parameters enters the superheater, and then passes to the adsorption unit. The use of a distillation column makes it possible to use regenerate in the dewatering circuit. Full automation of the process minimizes the human factor, guarantees high quality and environmental safety.

In the proposed installation, a type 3A molecular sieve (aluminosilicate) is used as a sorbent. The crystal structure of the molecular sieve and the pore size allow you to absorb molecules that are smaller than the size of water vapor molecules, while larger molecules (anhydrous ethanol vapors) pass into the sieve. This process is reversible, which allows you to repeatedly regenerate the sieve for use in a cycle. The service life of the screen is about 7 years. The cost of maintenance is low.

The closed cooling water circuit significantly reduces the amount of wastewater and makes the system economically and environmentally feasible.

The resulting anhydrous ethanol can be used as a gasoline additive called bioethanol. If rectified ethanol is dehydrated from food raw materials, the product is absolute food-grade ethanol used in the pharmacology and cosmetics industries.