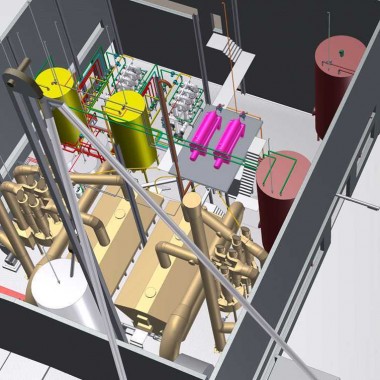

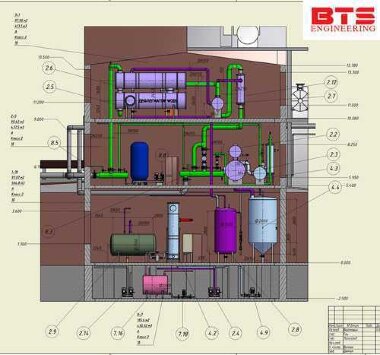

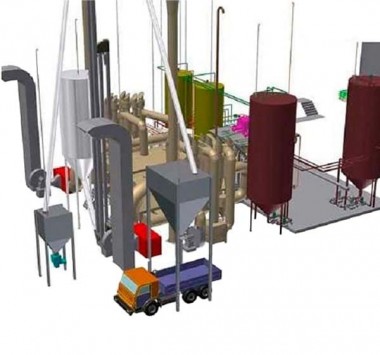

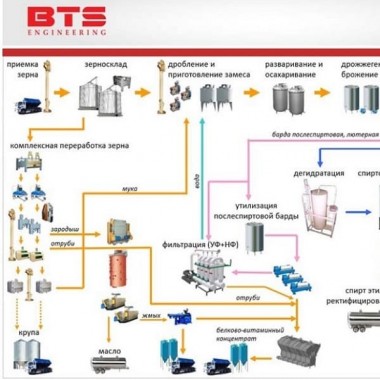

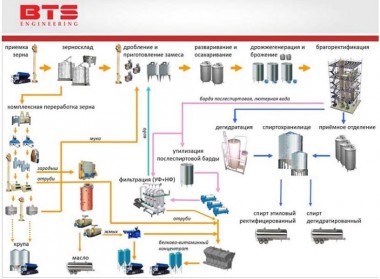

Complex grain processing for distilleries and bioethanol plants

The complex processing of starch-containing raw materials provides for the redirection of the components of grain for processing into marketable products.

For corn, this is:

a line for separating and processing the embryo to produce corn oil and cake, extracting cake, refining, deodorizing and vinterizing corn oil, a line for producing corn groats, a line for producing bran.

For wheat, this is:

the line for obtaining "vital gluten" or wheat gluten.

The general production technology and the number of branches are given here.

CORN FRACTIONATION PRODUCTS FOR ETHANOL PRODUCTION

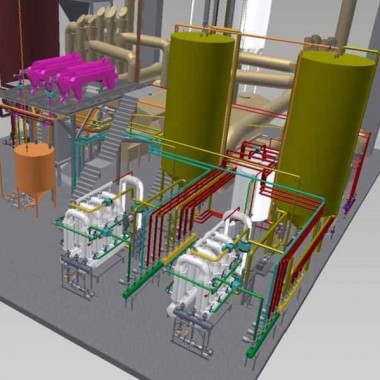

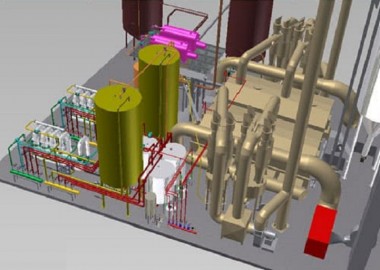

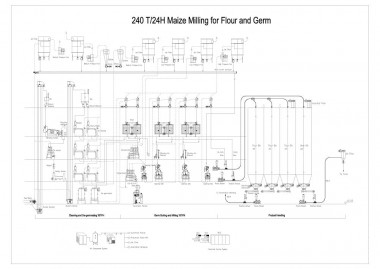

PURIFICATION AND FRACTIONATION, COMPLEX PROCESSING OF CORN GRAIN FOR THE DISTILLERY;

MECHANICAL AND ELECTRICAL EQUIPMENT

1. Grain cleaning system

- Machines for all departments (Automatic flow regulators, Magnets, Scales, Separator, Combinator, Grain humidifier)

- Aspiration system (Low pressure filter, Centrifugal fans, Muffler)

- Transport elements (Chain conveyors, Bucket burrows, Screw conveyors)

- Gravity flow system, Aspiration pipelines, Steel structures and mounting material

2. Degermination system

- Machines for all departments (Vibration loaders, Automatic flow regulators, Magnets, a device for moistening grain, a screw for preparing shells, Dezherminators, Sifting machines, Aspiration channels)

- Aspiration system (Low pressure filter, Centrifugal fans, Muffler)

- Transport elements (Chain conveyors, Bucket burrows, Screw conveyors)

- Gravity flow system, Aspiration pipelines, Steel structures and mounting material

3. Grinding system

- Machines for all departments (Four Roller machines, Sieving, aspiration channels, Vibrating screening machines, Impact fine grinding machines, Cyclone separators)

- Aspiration system (Low pressure filter, Centrifugal fans, Muffler)

- Transport elements (Chain conveyors, Bucket burrows, Screw conveyors)

- Gravity flow system, Aspiration pipelines, Steel structures and mounting material

4. Waste collection

- Transport elements (Screw conveyor)

- Aspiration pipelines, Steel structures and mounting material

5. Processing of finished products

- Machines for all departments (Automatic scales)

- Aspiration system (Low pressure filter, Centrifugal fans, Muffler)

- Transport elements (Chain conveyors, Bucket burrows)

- Gravity flow system, Aspiration pipelines, Steel structures and mounting material

6. Other equipment

- Compressed air line

- Purge air supply system

- Maintenance machines

- Plant monitoring elements

- Explosion protection ATEX zone 22

7. Electrical equipment

- Control system (PC/PLC control system and electrical cabinets)

- Electrical infrastructure of the process (cables for the process)

8. Supervision of installation and commissioning

- It is intended for mechanical and electrical supervision of installation and commissioning.

9. Engineering

- Delivery list:

- Consulting and know-how services (Expertise, calculation and specification of process equipment and accessories, project coordination and management)

- Delivery of documentation (drawings, tables, flow charts, etc.)

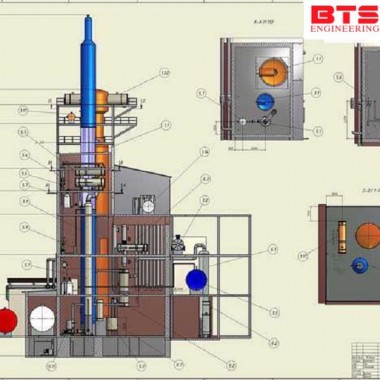

THE DEGERMINATOR DEVICE.

THE PRINCIPLE OF THE WORK OF THE DEGERMINATOR

GERM EXTRACTION

Corn germ

SHELLS EXTRACTION

THE ADVANTAGE OF TECHNOLOGIES FOR COMPLEX, FRACTIONAL PROCESSING OF CORN AT AN ALCOHOL, ETHANOL PLANT

- Excellent degermination and peeling, excellent results of high germs yields with a high fat content

- Low starch losses (less than 4%, based on whole grain)

- High availability of the plant

- Solution for high starch concentration in production

- Low power consumption

- Low operating costs of the department of complex grain processing

- High alcohol content in the brew 14%

- Absence of by-products during fermentation and rectification

- Energy efficiency

PRODUCT PREPARATION DEPARTMENT (COMPLEX GRAIN PROCESSING)

Increasing the range of products: cereals, cake, germ, bran, oils, etc.

Reduction of energy consumption and resources for alcohol production (parts of grain that do not contain sugar for alcohol production do not participate in the technological process)

Improving the quality indicators of alcohol, reducing impurities in the fermentation process.