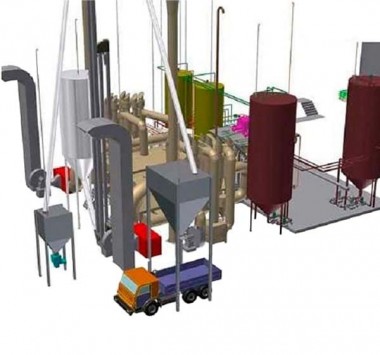

Proposal for the design and construction of a bioethanol plant 20000-50000 tons per year

As raw materials for plants with a capacity of 15000-20000 dal/day (40000-53000 tons/year), both starch-containing raw materials (grain, flour) and sugar-containing raw materials (beet molasses, sugar juice, sugar cane, sugar beet, etc.) can act as raw materials. Dehydrated ethanol is produced as an additive to fuel in the production of gasoline according to EU requirements (at least 5% of the total volume of gasoline). Complex processing of starch-containing raw materials is recommended. A full cycle of processing with the use of recuperative and recycling cycles is mandatory. The number of branches is from 10 to 11.

The general production technology and the number of branches are given here.

I-generation plant

(1). Acceptance and storage of grain;

(2). Crushing of grain and preparation of kneading;

(3). High-temperature hydrolysis of starch present in the batch (temperature 130 ... 150 C);

(4). Production of industrial yeast;

(5). Fermentation of hydrolyzed kneading (hereinafter referred to as wort) and obtaining a mature alcoholic mash;

(6). Distillation from a mature alcoholic mash and obtaining raw alcohol with a volume strength of 88%;

(7). Absolutization by azeotropic rectification using cyclohexane as a water absorber;

(8). Production of carbon dioxide. It is often economically unprofitable due to the high energy intensity (70...80% of the electricity consumption of the entire plant and the low quality of carbon dioxide);

(9). CIP station for washing process equipment;

(10). Technological boiler house with natural gas, fuel oil or coal;

(11). A warehouse of raw materials/finished products with a station for receiving/shipping to railway cars or motor vehicles;

(12). Cooling system of technological devices;

(13). Biological treatment facilities for the treatment of domestic and technological wastewater;

(14). Settling tanks for receiving alcohol stillage in native / raw form with a station for shipment to livestock farms.

The plant of the II generation

(1). Acceptance and storage of grain;

(2). Crushing of grain and preparation of kneading;

(3). Enzymatic dilution of starch, and its saccharification (temperature 65 ... 95 C);

(4). Production of industrial yeast;

(5). Fermentation of wort and production of mature alcoholic mash;

(6). Distillation of mature alcoholic brew and production of raw alcohol with a volume strength of 88%;

(7). Absolutization using molecular sieves as a water absorber;

(8). Carbon dioxide production-see the 1st generation plant;

(9). CIP station for washing process equipment

(10). Technological boiler house with natural gas, fuel oil or coal;

(11). A warehouse of raw materials/finished products with a station for receiving/shipping to railway cars or motor vehicles;

(12). Cooling system of technological devices;

(13). Biological treatment facilities for the treatment of domestic and technological wastewater;

(14). Production for the disposal of alcohol stillage in the form of a dry product-DDGS.

The plant of the III generation

(1). Acceptance and storage of grain;

(2). Separation of grain into its component parts in dry form. Redirection of components to the lines of their processing into marketable products:

- For wheat:

- The line for obtaining "vital gluten" or wheat gluten;

- A line of protein and vitamin concentrate;

- Production line for dry starch and glucose-fructose syrups;

- The bioethanol production line is based on the type of plants of the 2nd generation. Ceramic membranes can be used for absolutization, and alcohol stillage is sent to the production of protein-vitamin concentrate.

(3). Technological boiler house with natural gas, fuel oil or solid fuel. With a significant mass consumption of steam, it is rational to build a boiler cogeneration plant for its own generation of electric energy;

(4). Warehouses of raw materials and finished products with a station for receiving/shipping by rail or road;

(5). Cooling system of technological devices;

- The main processes of the third-generation plant technology:

- Grain acceptance and storage;

- Separation of grain into its component parts in dry form;

- Redirection of components to the lines of their processing into marketable products:

- For corn:

- The germ processing line with the production of corn oil and cake, extraction of cake, refining, deodorization and winterization of corn oil;

- A line of protein and vitamin concentrate;

- The production line of dry starch and glucose-fructose syrups with the processing of starches of groups A and B into syrups, and starch groups and pentosans - into bioethanol;

- The bioethanol production line, which includes:

- enzymatic dilution of starch and its saccharification (temperature 65 ... 95 C);

- production of industrial yeast;

- fermentation of wort and production of mature alcoholic mash;

- distillation from a mature alcoholic brew and production of raw alcohol with a volume strength of 88%;

- absolutization of raw alcohol using molecular sieves as an absorber;

- alcohol stillage is sent to the production of protein and vitamin concentrate.

For wheat:

- The line for obtaining "vital gluten" or wheat gluten, and then-according to the scheme of processing corn;

- For both schemes of processing of various types of raw materials (corn/wheat), the following are necessary:

- Technological boiler house, a heat carrier operating on natural gas, fuel oil or solid fuel. With a significant mass consumption of steam, it is rational to build a boiler cogeneration plant for its own generation of electric energy;

- Warehouses of raw materials and finished products with a station for receiving/shipping by rail or road;

- Cooling system of technological devices;

- Biological treatment facilities for the disposal of domestic and industrial wastewater;

- Industrial water supply system with water intake, treatment and transportation units;

- CIP-washing system of technological equipment;

- Systems for the supply of organic fuel and the disposal of its combustion products;

- The power supply system, which includes the plant's own cogenerating capacities;

- The system of automatic control, alarm and control of technological cycles.