Mineral, inert, refractory balls

Mineral, inert and heat-resistant balls are special substances in the form of balls that are used to support and close the catalyst in the systems of the chemical and oil refining industries. The main function of the material is to provide normal support and resistance to catalytic columns and act as a certified filler to optimize and ensure the normal flow of industrial processes. Bullets are able to protect less dense catalysts and improve the chemical properties of liquids and gases involved in the industry.

Advantages of using high-quality inert and heat-resistant balls in industry.

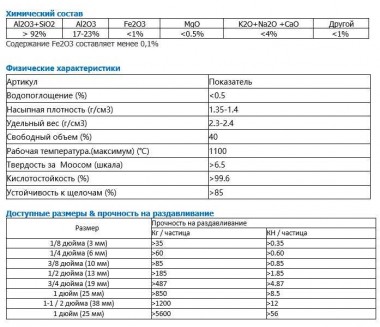

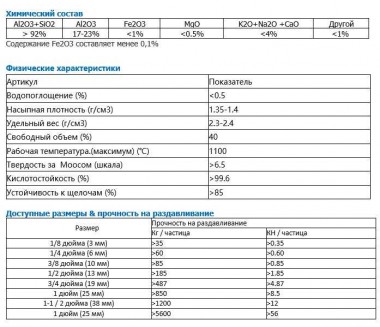

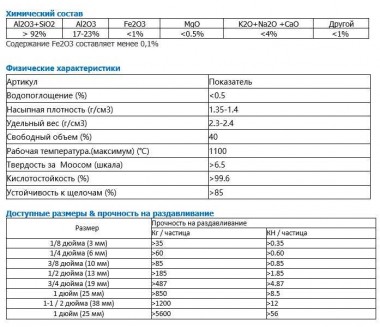

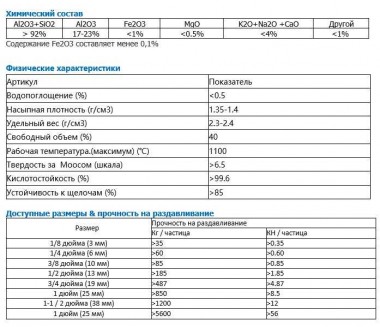

Ceramic balls are made on the basis of aluminum oxide. They are quite resistant to deformations and elevated temperatures: they can withstand up to 700 degrees Celsius, provided that they are evenly heated at 100 degrees per hour. The material is presented as round crumbly units with a diameter of 0.3 - 50 mm, depending on the production needs. Among the advantages of using such a filler in industrial processes, it is necessary to note:

- High heat resistance;

- High pressure resistance;

- Low water absorption;

- Stability in chemical reactions;

- Resistance to interaction with acids, alkaline substances and organic solvents;

- Resistance to moderate temperature changes.

The material is distributed in polyethylene bags or cardboard boxes. Please check the price and desired packaging form with the managers of the online store after placing the order.

Areas of use of heat-resistant and inert balls in industry.

Most often, such a filler is used to speed up the process of separating gas and liquid in the system and protect the catalyst during industrial processing processes. Preferably, it has significantly lower mechanical strength, so the use of such filling is mandatory.

Among the most common areas of use, it is worth noting:

- Oil refining industry;

It can be used as a filler during hydrotreating, hydrogenation, hydrocracking, isomerization, and in Klaus reactors.

- Petrochemical industry;

It can be used as a filler during hydrotreating, hydrogenation, desulfurization, absorption, oxidation, separation, ethylene cracking, polymerization.

- Gas processing industry;

It can be used as a filler during the processes of drying, liquefaction of gas, gas processing, in Klaus reactors.

- In other chemical-related industries;

It can be used as a filler for the production of ammonia, ethylene or as a molecular sieve, where physical properties allow it.