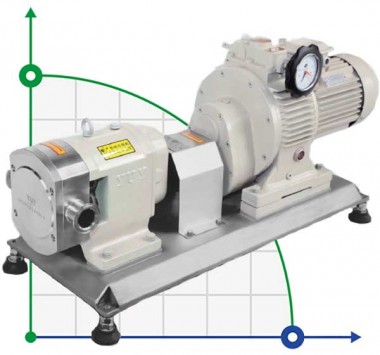

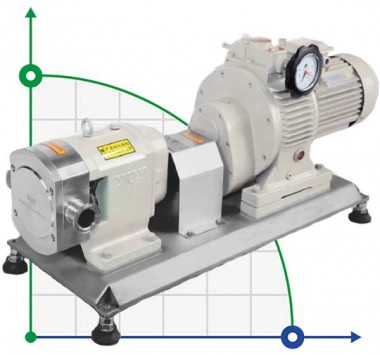

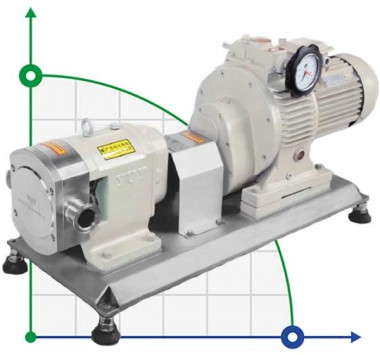

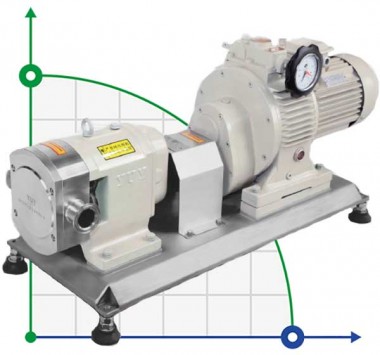

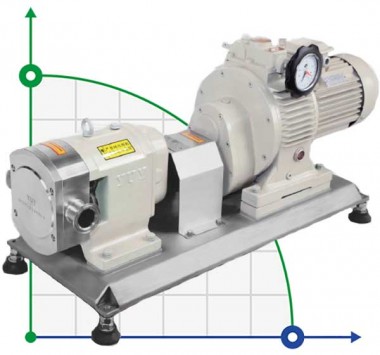

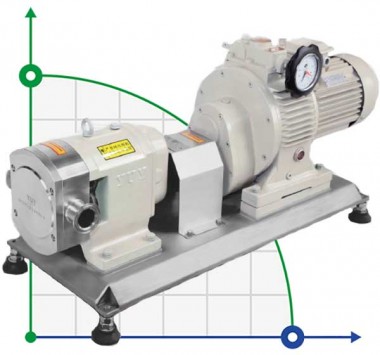

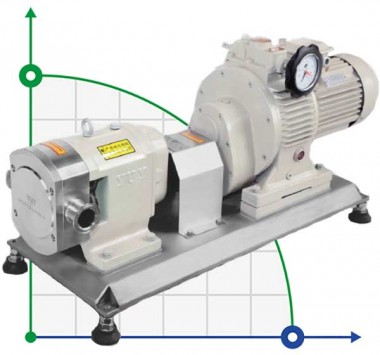

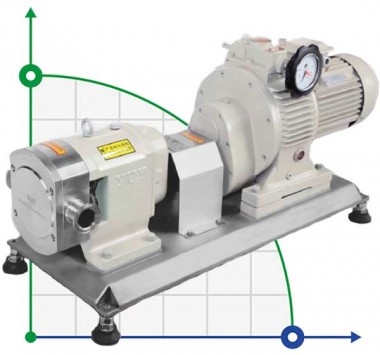

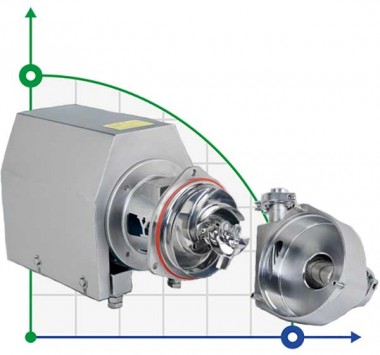

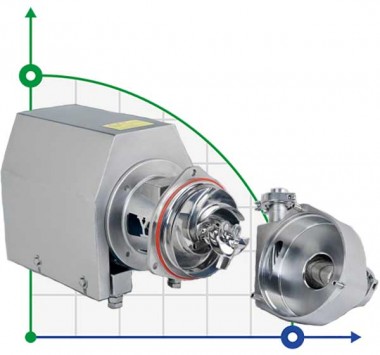

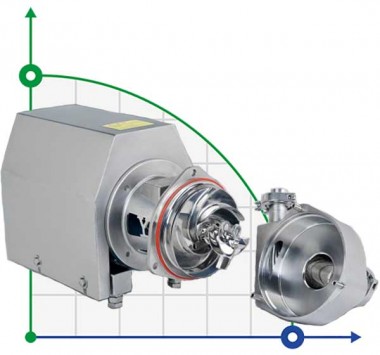

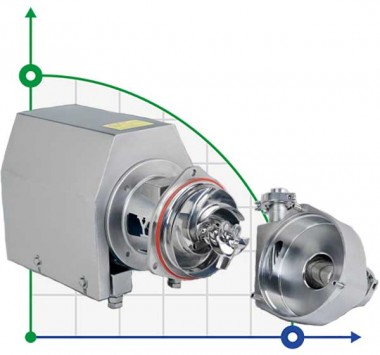

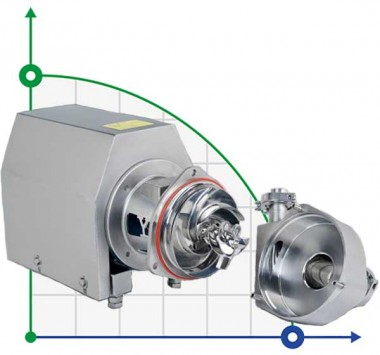

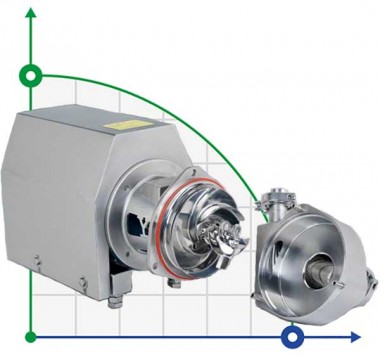

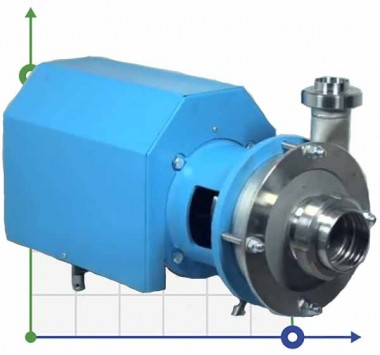

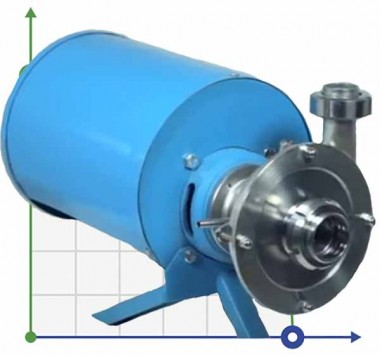

Sanitary, hygienic pump

Sanitary and hygienic pumps are devices that serve for pumping various liquids and are characterized by an increased degree of hygiene. They are usually used where industrial pumps are not suitable for their physical properties. Hygiene pumps are made of materials that do not react with the liquid moving through the system. The design of the device provides for the absence of solution residues in order to reduce the possibility of fermentation or stagnation of water. Thus, it is possible to maintain the maximum purity of the transported liquid and ensure normal sanitary conditions. Most often, such devices are used to pump solutions in the food or pharmaceutical industry.

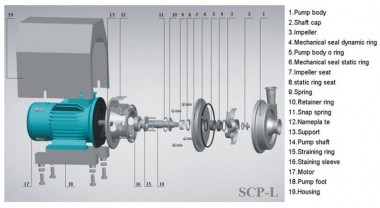

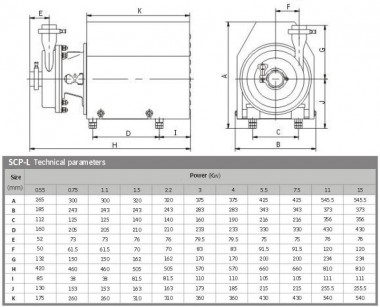

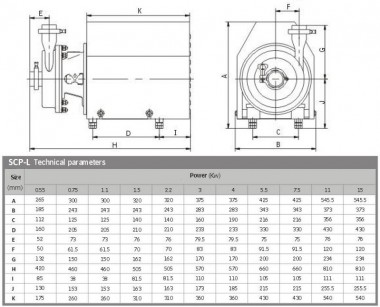

Among the varieties of models, sanitary pumps are presented in the form of single - stage centrifugal pumps that have an open or semi-open impeller. Stainless steel is used as the main material. This material is quite resistant to aggressive liquids and ensures long-term operation of the device without deformations.

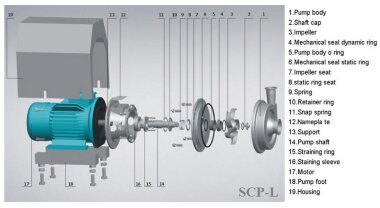

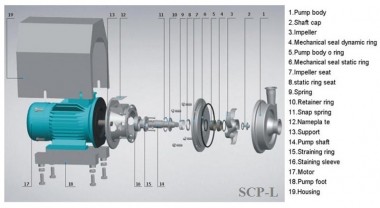

Design features of hygiene pumps.

The main feature of sanitary and hygienic pumps is the materials of their manufacture. As already mentioned, it is mainly stainless steel, which allows you to maintain a stable chemical composition of the transported liquid. Additionally, instead of sandblasting the steel surface, an electric one is used. This allows you to ensure maximum smoothness and the absence of microdeformations, which over time become clogged with liquids and affect the quality of sanitary conditions. Additionally, among the advantages of such pumps, it is worth highlighting:

- Simplicity of design;

- Simple design and a small number of spare parts for replacement or repair;

- Specially adapted manufacturing materials;

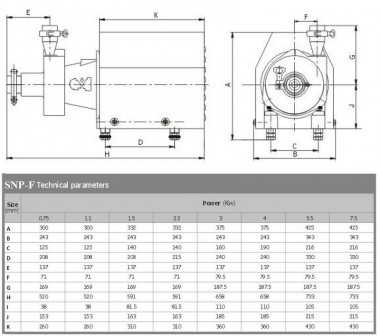

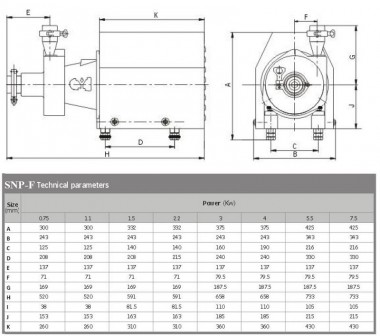

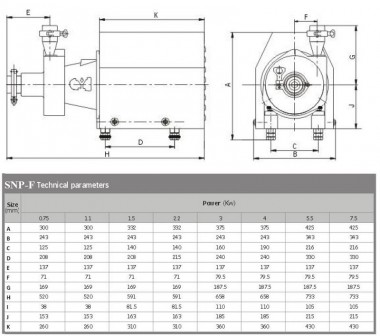

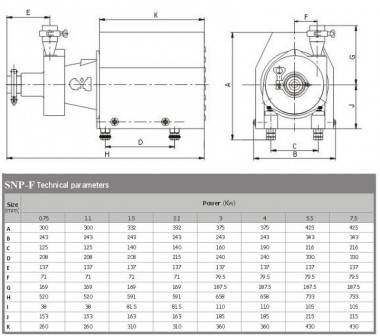

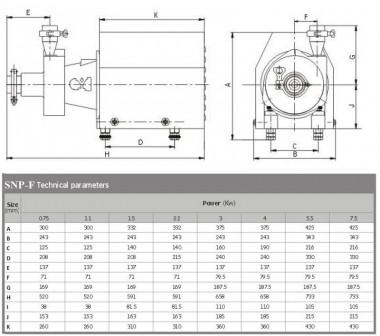

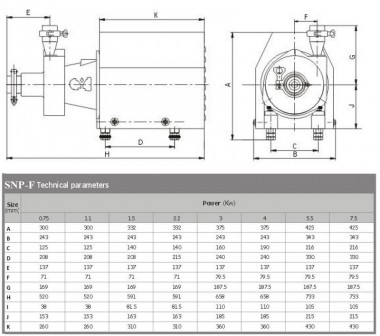

- Compact size;

- High productivity and efficiency;

- A small price;

- Low electrical energy costs;

- Ability to work with viscous mixtures;

- Wide range of applications.

Such pumps can be used mainly in the food industry for pumping any products of liquid or easily viscous consistency. It can be dairy products, fats, juices, dough, etc. Less often, such pumps are used in pharmaceuticals or, for example, cosmetology. They can also be used in the alcohol industry or other chemical processes where it is necessary to maintain sterility and the required level of sanitary requirements.