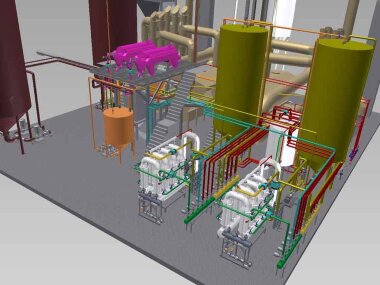

Modernization of the distillery 6000-10000 dal / day

Plants with a capacity of (2000-3000 dal/day (5300-8000 tons/year)) ethanol is produced both from starch-containing raw materials (grain, flour) and from sugar-containing raw materials (beet molasses, sugar juice, sugar cane, sugar beet, etc.). it is planned to produce both rectified ethanol and dehydrated ethanol. Rectified ethanol, produced from starch-containing raw materials, is used mainly in the liquor industry and high requirements are imposed on it in terms of the content of impurities and organoleptic parameters. For ethanol produced from sugar-containing raw materials ("higher purification"), there are no special requirements for organoleptics for the reason that this grade of ethanol is mainly used in medicine, perfumery, antiseptics, etc. If dehydrated ethanol is produced, it is used as an additive to fuel in the production of gasoline according to EU requirements (at least 5% of the total volume of gasoline). It is economically feasible to establish a full cycle of processing of raw materials at enterprises of this productivity (or complex processing of starch-containing raw materials).

This offer provides for the participation of our company in the construction of a new plant (technological support of the project, production and supply of equipment, supervision and commissioning of both individual sections and the entire complex as a whole).

The offer is made in such a way that allows you to approximately determine the cost part, for technological equipment, for the customer as a whole and for each site separately. We have indicated approximate prices for our equipment and for the one that is purchased or manufactured locally.

We also carry out the entire complex of works on the design, installation and commissioning of an automated control system for the technological process of alcohol production. Automation of the technological process can be developed both for the plant as a whole and for individual production sites, within the limits that ensure stable production of alcohol of the Lux brand. The cost of production automation is determined by the volume of automated sites, the tasks set and the choice of actuators.

-

The offer does not include:

- sewage and industrial effluents;

- heat supply, water supply, construction work.

These works are carried out, as a rule, by local specialized organizations and require clarification and coordination.

We hope that this information will help the customer to solve the tasks facing him faster and easier.

Consumption of energy resources, water and grain by an alcohol plant with a capacity of 6000 dal/day

The energy consumption for technological needs for the production of 6000 dal of alcohol during saccharification with enzyme preparations will be 2350 kWh / day.

The steam consumption for technological needs for the production of 6000 dal of alcohol during saccharification with enzyme preparations will be 400 t / day, i.e. 16.6 t / h, which will be ≈ 1300 m3 of gas per hour.

The water consumption for technological needs for the production of 6000 dal of alcohol during saccharification with enzyme preparations will be 22000 m3/day, including 480 m3 of drinking water, i.e. 890 m3/h and 20 m3/h, respectively.

The consumption of grain for the production of 1000 dal of alcohol, depending on the culture and starchiness, will be ≈ 150 t/day.

This offer is for informational purposes and is not an offer.

Order a technical and commercial proposalThe general production technology and the number of branches are given here.