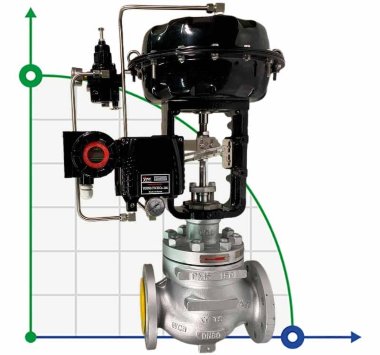

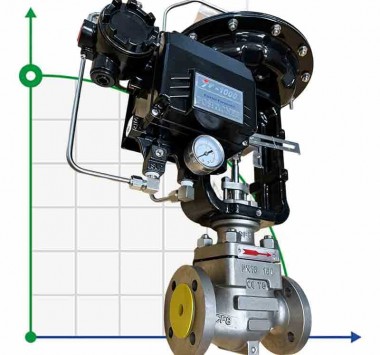

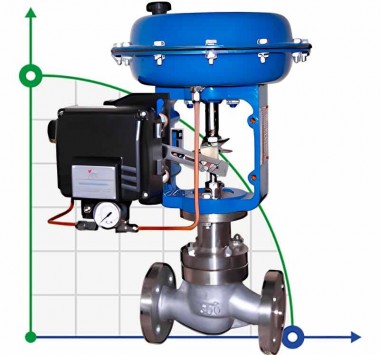

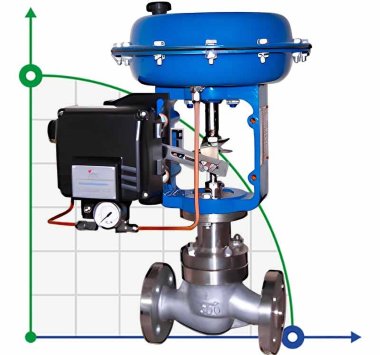

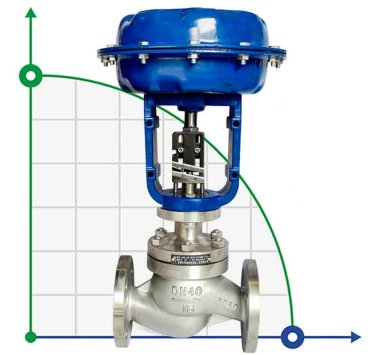

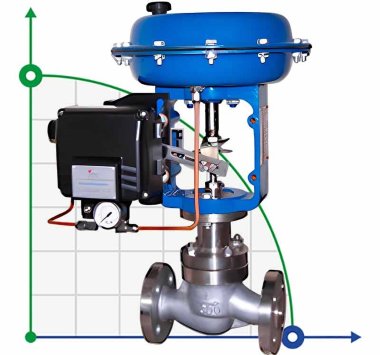

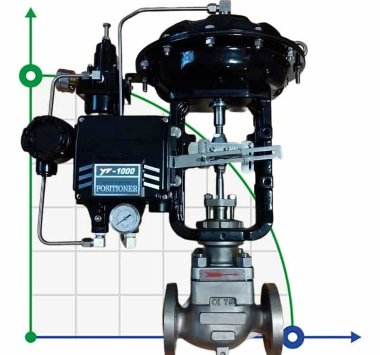

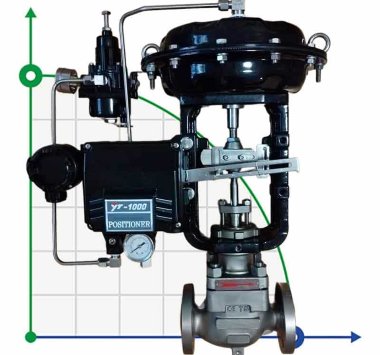

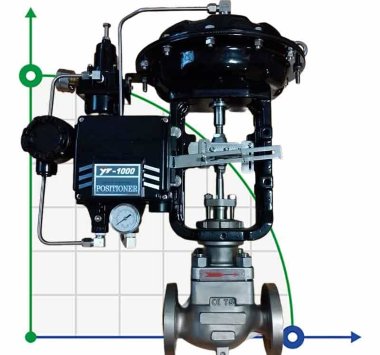

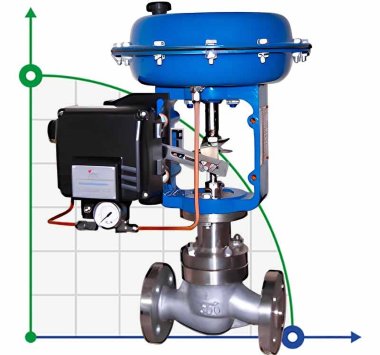

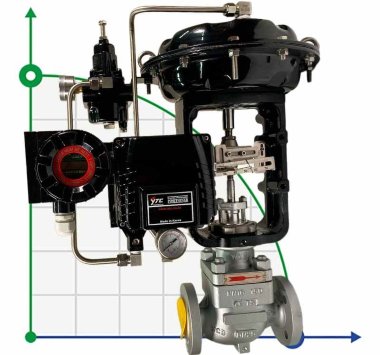

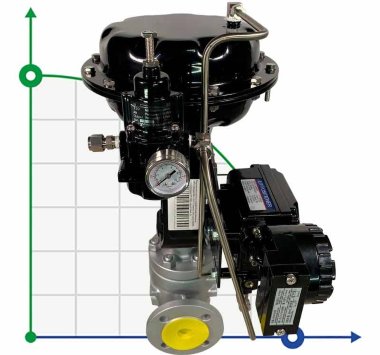

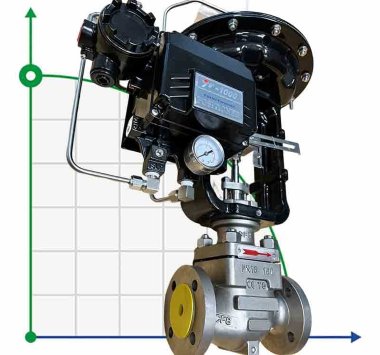

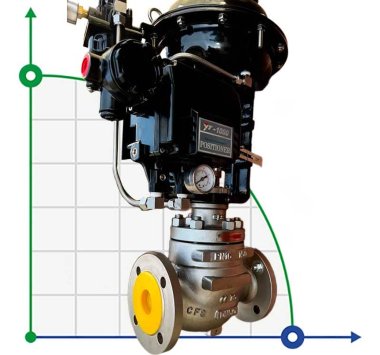

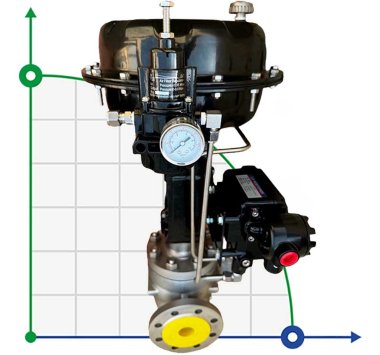

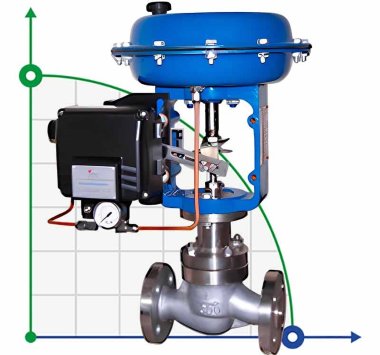

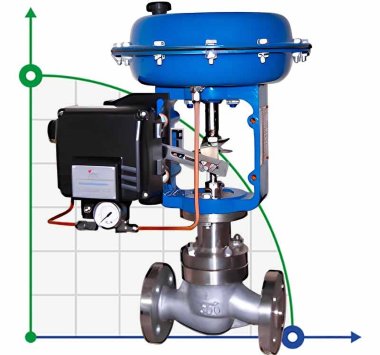

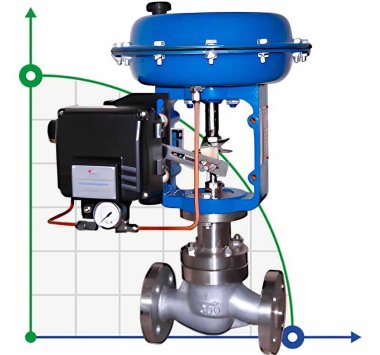

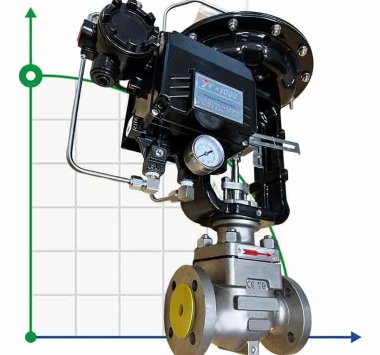

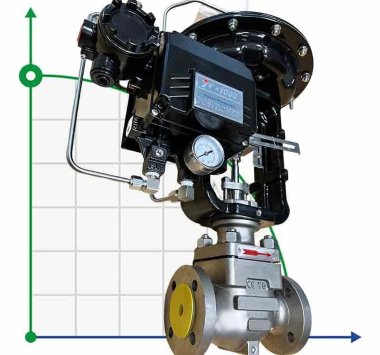

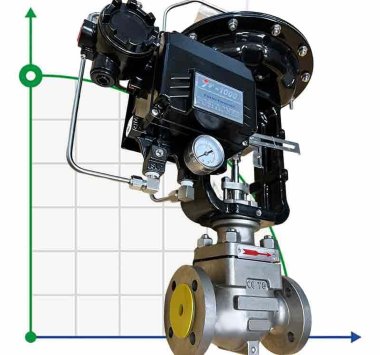

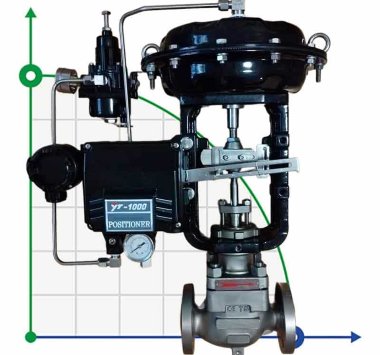

Control valves with positioner and pneumatic actuator

Control valves are a type of pipeline fittings designed to control the flow of a working medium and, as a result, perform regulation and control of such physical parameters as flow, pressure and temperature. The most widespread are seat-type control valves, in which the cross-sectional area of the valve changes due to a specially shaped movable valve moving in a seat mounted in the valve body, allowing a smooth change in the throughput - the flow characteristic of the control valve. The valves are actuated by various linear actuators: electric or pneumatic actuators.

Control valves can be found in any automated process control systems: hot water and steam boilers, heating and water supply systems, steam, water and gas pressure reduction units, on heat exchangers and in other industrial processes and industries.

Often shut-off valves have an electric or pneumatic drive. Thanks to this, it can be automatically triggered in the event of an unforeseen situation, for example, a pipe burst.

What are the pros and cons of shut-off and control valves?

Shut-off and control valves of different types have different advantages and disadvantages.

Advantages of globe valve:

- universal option;

- can be used in neutral and aggressive environments;

- withstands high pressure and temperature;

- easy to install due to its size.

Disadvantages include the presence of resistance to moving substances.