Pressure reducing valves

A pressure reducing valve is a type of control valve designed to reduce and maintain the pressure after the valve at a given level.

According to their design, there are three main types of pressure reducing valves:

- direct acting pressure reducing valves with diaphragm actuator;

- bellows pressure reducing valves;

- pilot operated valves.

Below we will consider the specified types of valves in more detail.

Advantages:

- high throughput;

- low requirements for steam quality (degree of steam dryness, steam purity – presence of abrasive particles).

The disadvantages of this type of valve include:

- low speed of regulation;

- low control accuracy;

- small reduction ratio (many manufacturers state it at 1:2, 1:4 and in rare cases 1:10).

The pressure reduction ratio is the ratio of the pressure at the valve outlet to the pressure at the valve inlet. The need to use a condensate tank*.

* This feature increases the chances of personnel error during maintenance. The lack of coolant can lead to failure of the valve diaphragm drive due to damage to the rubber diaphragm.

Based on all the above, direct acting pressure reducing valves with diaphragm actuator are suitable for use in systems with high steam flow, small pressure reduction ratio, constant load and low steam quality.

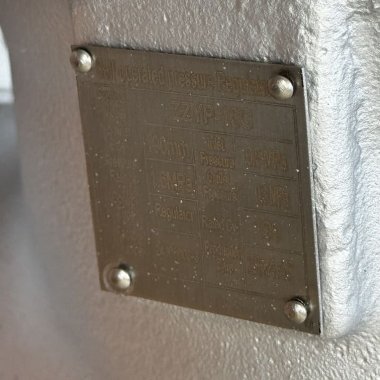

Bellows pressure reducing valves have a number of advantages for their use:

- low cost compared to other types of valves;

- small dimensions and weight;

- low requirements for steam quality. But higher than for valves with diaphragm drive;

- absence of external impulse tubes.

The disadvantages of this type of valve include:

- low throughput;

- low accuracy and speed of regulation.

Thus, it is advisable to use valves of this type as individual pressure-reducing valves for machines with low flow rates, constant loads and relatively low steam quality.

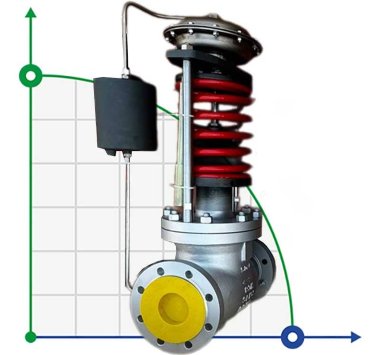

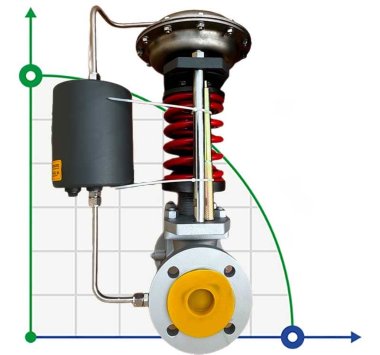

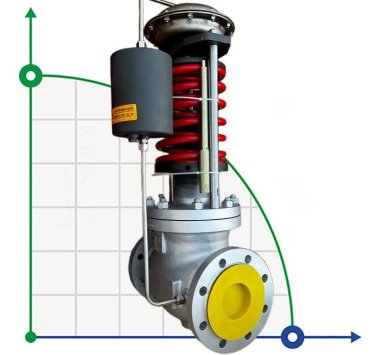

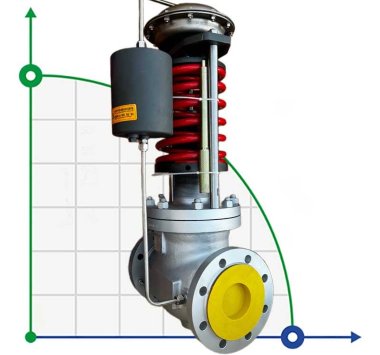

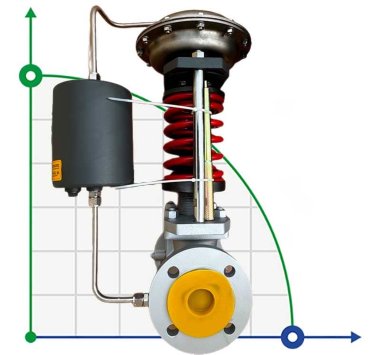

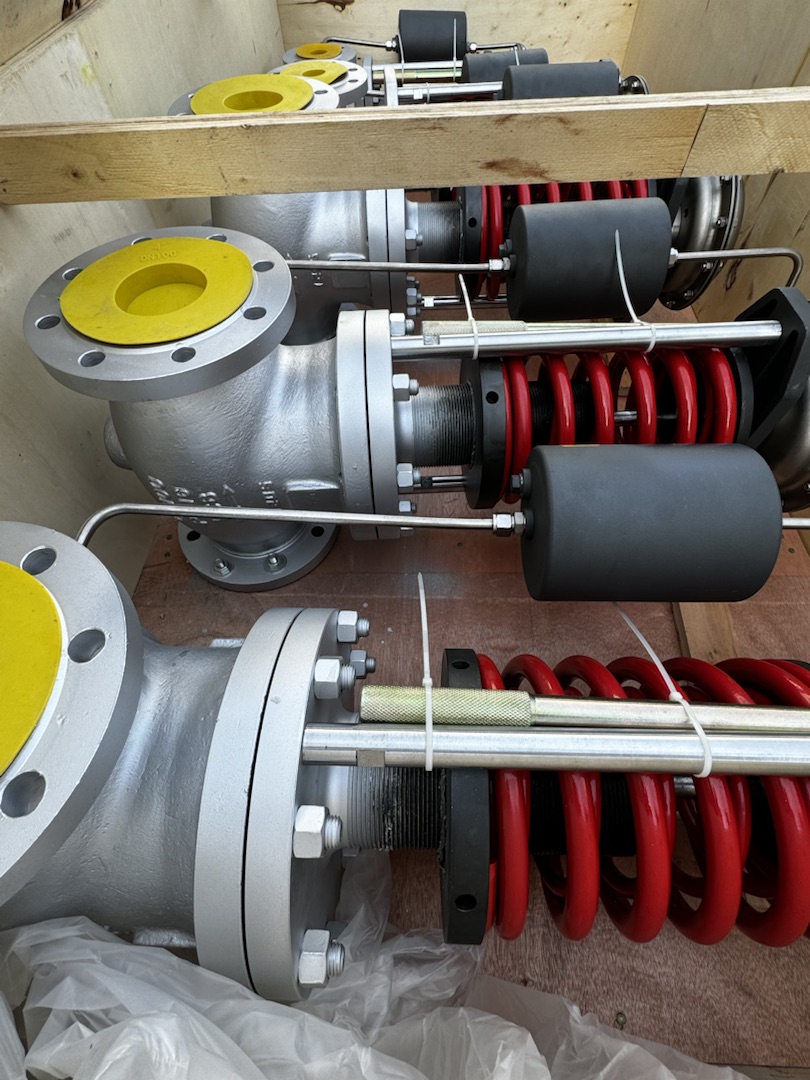

Pilot operated pressure reducing valves

Pilot-operated pressure reducing valves can be divided into two groups:piston and diaphragm valves.

The main advantages of this type of valves are:

- high speed regulation;

- high control accuracy;

- high reduction ratio (1:20);

- operation over a wide range of bandwidths;

- piston valves are designed for low and medium flow rates (up to 10 t/h);

- membrane valves have increased throughput capacity (up to 30 t/h);

- no need to use a condensate tank and no external impulse tubes.

The disadvantages of pilot valves include increased demands on the quality of steam (its degree of dryness and purity)*.

* To achieve high steam dryness, steam separators should be used, and steam purity can be ensured by installing a mesh filter.

Based on the above-described advantages of pilot valves, it can be concluded that these valves are suitable for a wide range of tasks, including such as operation with a large reduction ratio and/or operation in systems with variable loads.

The selection of a pressure reducing valve should begin with the selection of the valve type/design (direct acting/bellows/pilot) based on the following system parameters:

- range of steam consumption and its constancy;

- pressure reduction ratio (pressure before and after the valve);

- rate of load change;

- steam quality.