Products from the same category

1057321

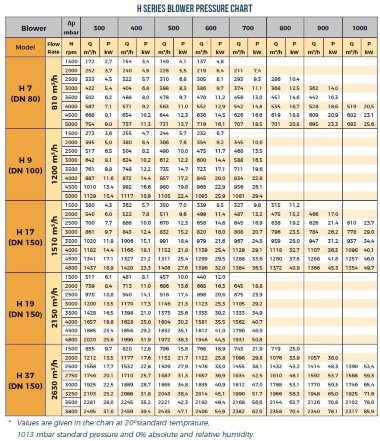

Blower RUUT BLOWER H37 (DN150/PN10), 1200 m3/h, 2100 rpm, with 37 kW motor, 380V, 50Hz, on frame

$14,976

Pre-order only

1057322

Blower RUUT BLOWER H37 (DN150/PN10), 1500 m3/h, 2500 rpm, with 45 kW motor, 380V, 50Hz, on frame

$15,371

Pre-order only

Description

The principle of operation: blowers consist of a pair of rotors rotating in a body of a certain shape with positive displacement. The movement of the rotors is synchronised by the distribution gears on the shafts. Therefore, there is no friction between the rotors and between the rotors and the casing. During the rotation, the air is displaced by the gears and transferred to the discharge side. Blowers deliver as much air as their volume during each revolution of the pump shaft. The capacity of a blower depends on its operating speed and pressure (resistance) conditions. Blowers generate pressure depending on the connected system resistance and can be operated under pressure or vacuum.

Application of the H series blower:

- Pneumatic conveying of granular materials (pressure and vacuum)

- water treatment procedure at wastewater treatment plants (pressure)

- ventilation of swimming pools at fish farms (pressure)

- central dust and smoke removal system (vacuum)

- sandblasting systems (pressure)

- Drying systems (pressure)

- ventilation systems (pressure and vacuum)

Documentation Blower RUUT BLOWER H 7 (DN 80), 810m3/h

Download instructions, catalog for Blower RUUT BLOWER H 7 (DN 80), 810m3/h