Products from the same category

Description

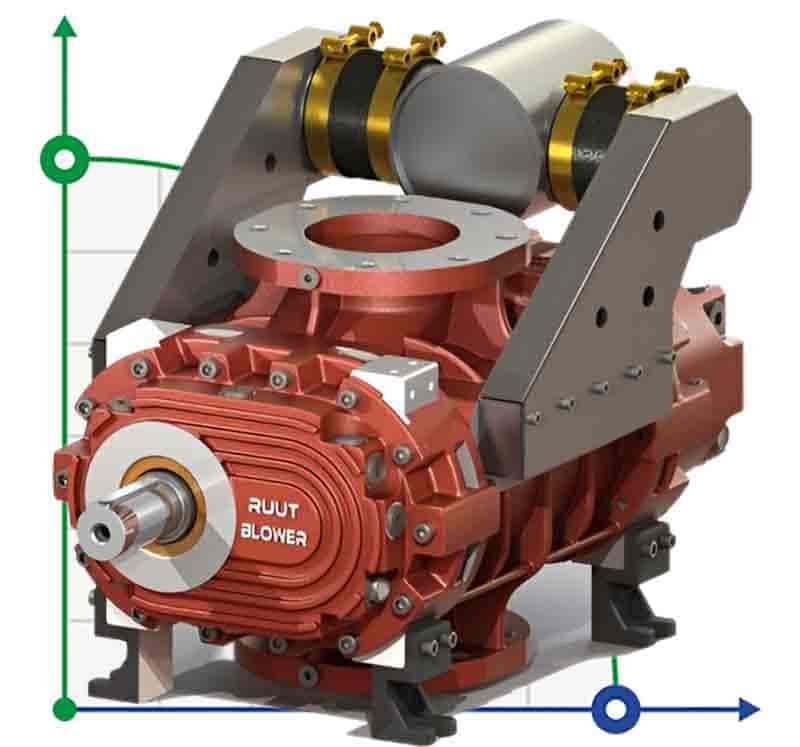

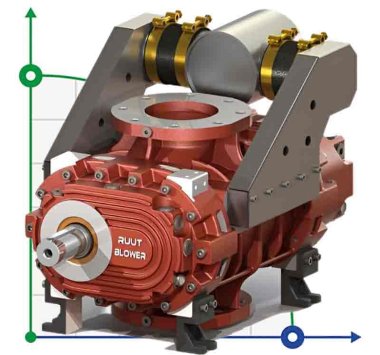

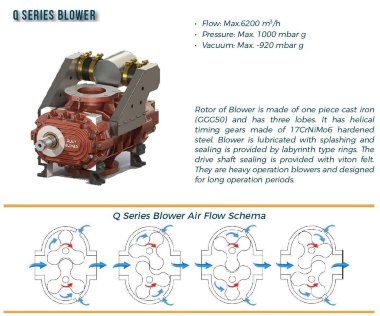

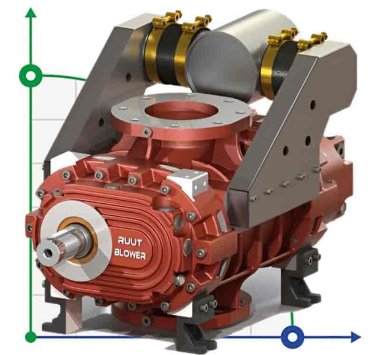

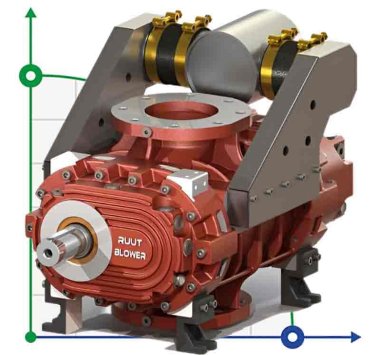

The principle of operation: blowers consist of a pair of rotors rotating in a body of a certain shape with positive displacement. The movement of the rotors is synchronised by the distribution gears on the shafts. Therefore, there is no friction between the rotors and between the rotors and the casing. During the rotation, the air is displaced by the gears and transferred to the discharge side. Blowers transfer as much air as their volume during each revolution of the pump shaft. The capacity of the blower depends on its operating speed and pressure (resistance) conditions.

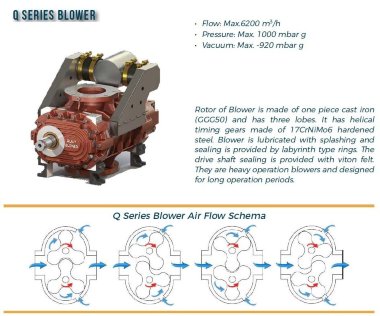

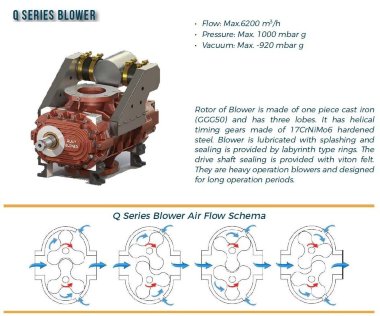

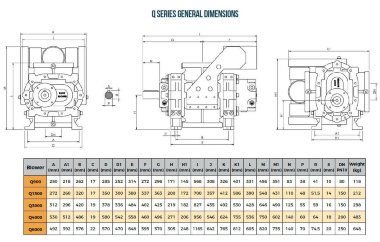

The rotor of the Q series blower is made of solid cast iron (GGG50) and has three lobes. It has helical gears made of 17CrNiMo6 hardened steel. The blower is splash lubricated and sealed by labyrinth-type rings. The sealing of the drive shaft is provided by wind felt. These are heavy duty blowers designed for continuous operation.

Application of the Q series blower:

- Pneumatic conveying of granular materials (vacuum);

- centralised dust collection system (vacuum);

- central milking machines (vacuum);

- central vacuum systems (vacuum);

- in loading equipment (vacuum).

Documentation Blower RUUT BLOWER Q 1500 (DN 150), 1600m3/h

Download instructions, catalog for Blower RUUT BLOWER Q 1500 (DN 150), 1600m3/h