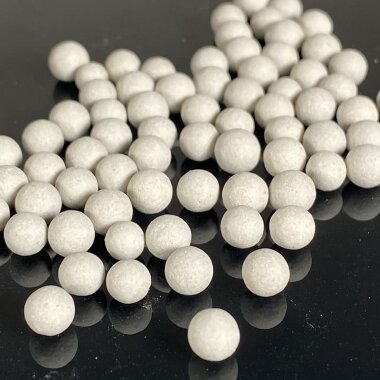

Ceramic Balls

Sort by:

RP inert ceramic balls are widely used as catalyst and adsorbent bed support material in refining, petrochemical, and gas processing industries, with unmatched shock strength, thermal resistance and crush strength.

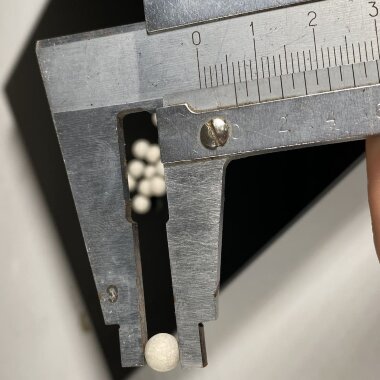

Available sizes: 1.5mm, 3mm, 6mm, 10mm, 13mm,16mm, 19mm, 25mm, 30mm, 38mm, 50mm, 75mm

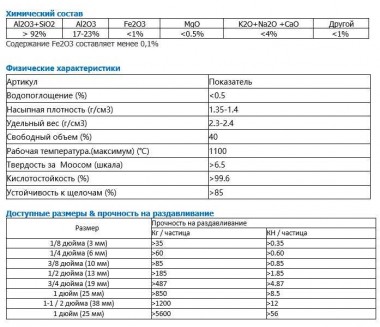

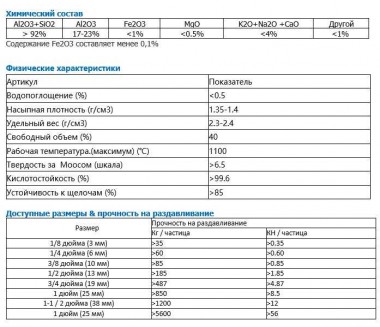

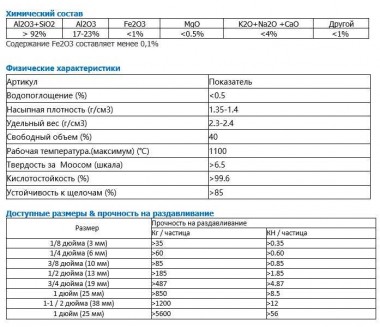

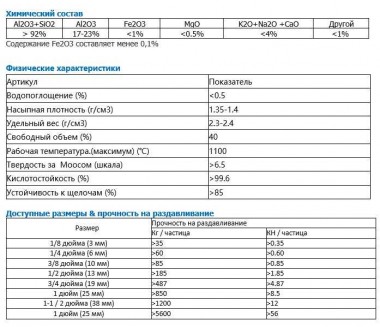

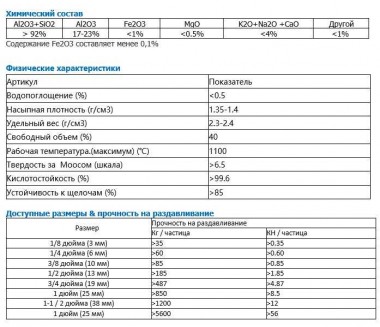

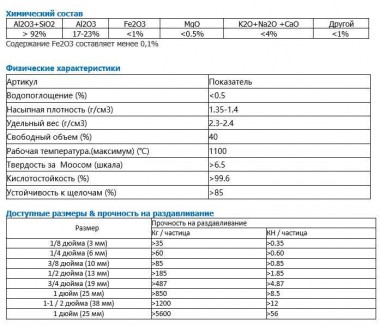

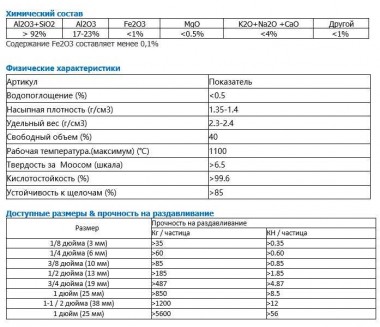

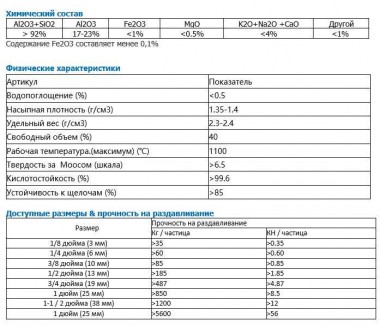

SPECIFICATION

| Chemical composition | |||

RP-19 |

RP-99 |

||

| Property | Unit | Value | Value |

| Si02 | % | 70-74 | ≤0.2 |

| Al2O3 | % | 18-22 | ≥99.0 |

| SiO2+Al2O3 | % | ≥92 | — |

| Fe2O3 | % | ≤1.5 | ≤0.05 |

| CaO | % | ≤0.6 | ≤0.1 |

| TiO2 | % | ≤0.2 | ≤0.05 |

| MgO | % | ≤0.76 | ≤0.05 |

| K2O | % | ≤3.2 | ≤0.05 |

| Na2O | % | ≤1 | ≤0.2 |

| Leachable Iron | % | Less than 0.03 | — |

| Physical properties | |||

| Property | Unit | Value | Value |

| Void factor | % | 40 | 40 |

| Water absorption | wt. % | ≤1 | ≤3 |

| Hardness | Mohs | ≥7 | ≥8 |

| Particle density | gm/cc | 2.3-2.4 | 3.56 |

| Bulk density | kg/m³ | 1380-1400 | 2000-2200 |

| Maximum operation temperature | °C | 980 | 1800 |

| Acid resistance | % | 99.6 | — |

| Alkali resistance | % | 85 | — |

Crush Strength

| Size, mm (inch) | Unit | Value | Value |

| 3mm (1/8") | lbs(kg) | ≥88 (40) | ≥200 (90) |

| 6mm (1/4") | lbs(kg) | ≥180 (82) | ≥450 (205) |

| 10mm (3/8") | lbs(kg) | ≥330 (150) | ≥880 (400) |

| 13mm(1/2") | lbs(kg) | ≥600 (273) | ≥1870 (850) |

| 19mm(3/4") | lbs(kg) | ≥1320 (600) | ≥3520 (1600) |

| 25mm(1") | lbs(kg) | ≥2200 (1000) | ≥5500 (2500) |

| 30mm(1-1/4") | lbs(kg) | ≥2200 (1000) | ≥5500 (2500) |

| 38mm(1-1/2") | lbs(kg) | ≥2600 (1182) | ≥6600 (3000) |

| 50mm (2") | Ibs(kg) | ≥3000 (1362) | ≥8800 (4000) |

Typical Application:

Refinery Industry:

- Desulfurization

- Hydrocracking

- Hydrogenation

- Reforming

- Isomerization

- Claus Reactors

Ammonia Plants:

- Desulfurization

- Hydrotreating

- Methanation

- Reforming

- Molecular Sieve

Petrochemical Industry:

- Dehydrogenation

- Crude oil cracking

- Oxychlorination

- Oxo process

- Desulfurization

- Ethylene cracking & drying

- Polymerization

Gas Processing Industry:

- Dryers

- LNG Prepurifiers LPG Treaters

- Mercury Removal from Natural Gas

Industrial Gas Processing Industry:

- Air Prepurifiers

- Dryers

Acid Production:

- Separation

Package

25kg PP bags; 1MT PP super sacks; 1CF Carton Box; 150L/200L steel drums; etc

Sale