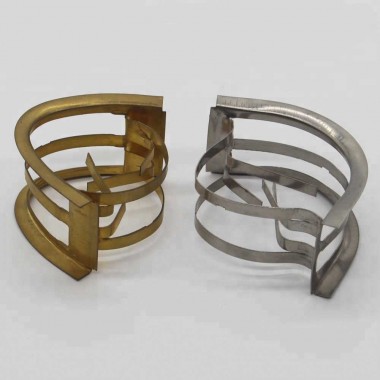

RING-I Saddle Packing

In comparison to Pall rings, this packing increases capacity and efficiency.

Construction materials:

only metal.

Metal Intalox Saddle was developed by the United States Norton, between the shape of its saddle-shaped ring and between, and the advantages of both. Intalox metal structure in the saddle-shaped packing ring based on the increase of the annular tendon, to avoid overlap and ensure a certain degree of strength and rigidity out of a number of small claws, an increase of gas-liquid agitation, enhanced mass transfer, thus produce a unique performance. Metal Intalox Saddle is referred to as domestic-shaped locks Intel fill, enjoy a high international reputation. This new type of efficient packing for the new equipment, packed tower, plate tower height lower than 35%, 30% decrease in diameter, or increase the efficiency of 10-30%, 20-60% reduction in pressure loss. Domestic wet instead of dry distillation distillation pilot study showed that 20 percent can reduce the investment. In short, the use of a new type of ring can be increased Intalox yield or low power costs and improve separation efficiency. Metal Intalox Saddle can be a variety of materials, such as carbon steel, stainless steel 304, 304L, 410, 316, 316L, etc. to choose from.

| Type | Nominal Size | Specific Surface | Void Factor | ||

| mm | inch | m²/m³ | ft²/ft³ | % | |

| 15 | 15 | 5/8 | 300 | 91.5 | 97 |

| 25 | 25 | 1 | 225 | 68.6 | 97 |

| 40 | 40 | 1-1/2 | 155 | 47.3 | 98 |

| 50 | 50 | 2 | 102 | 31.1 | 98 |

| 70 | 70 | 2-3/4 | 60 | 18.3 | 98 |