Products from the same category

Description

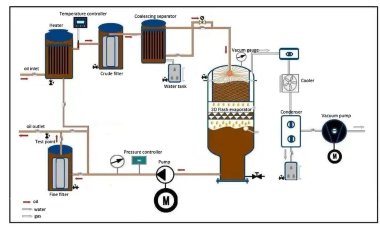

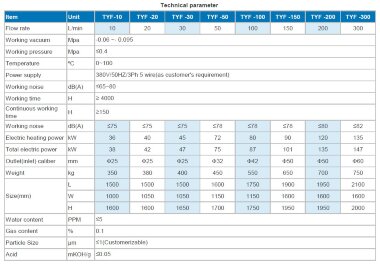

The use of XLDZJ-150S two-stage vacuum oil filter: used for the regeneration and purification of poor quality transformer oil, turbine oil, diesel oil, hydraulic oil, anti-wear oil, oil and other insulating oil, degassing, dehydration and filtration of impurities, drying of transformer insulation and insulating oil on site. Vacuum oil injection into electrical equipment.

Low temperature oil-water separation technology, can effectively remove molecular water from oil.

The use of stainless steel material as the filter element can effectively remove impurities in the oil, long service life, no need to add any additives in the process of use, after the processed oil contains impurities with a particle size of 3 microns, the purity has reached NAS 6.

The company uses its own and unique foam extinguishing technology to ensure the automatic balance of imported oil in the oil filter process.

Using a combination of stereoscopic flash and aggregation separation technology, the content of the processed oil can reach a water content of less than 5 PPM.

Can work online for more than 200 hours.

Set upper and lower limits for temperature control to ensure the service life of electrical components.

The multi-stage filter and molecular adsorption technology are adopted, and the filter element is encrypted step by step to ensure the accuracy of the filter; all filter elements are stainless steel filter material, which can be used repeatedly without frequent replacement, with longer service life and higher accuracy than domestic filter material.

Low-temperature oil treatment technology: conventional aggregation separation and flash can effectively remove ordinary water in oil, but molecular water is not easy to remove; and micro-wire in oil, not only oil after treatment, but also easy to emulsify again, and the use period is very short; The introduction of Japanese low-temperature oil treatment technology easily solves the removal of molecular water, micro-wire in oil, not only quickly, but also longer, thus better protecting mechanical equipment and prolonging the service period.

Special combination of liquid level and solenoid valve: at present, part of the household oil filter usually uses a single solenoid valve control, this control mode is very unstable, often produces flowing oil, which not only pollutes the vacuum pump oil, so that the service life of the vacuum pump is shortened, the oil from the vacuum pump pollutes the environment in the workplace. We use infrared and solenoid valve combined with effective control to make the oil filter run more stably and not cause oil leakage due to the phenomenon of vacuum pump, to achieve the safety of automatic online oil filter, truly achieve man-machine separation.

Documentation Two-stage vacuum transformer oil cleaning station XLDZJ-150S

Download instructions, catalog for Two-stage vacuum transformer oil cleaning station XLDZJ-150S

Good price