Products from the same category

Description

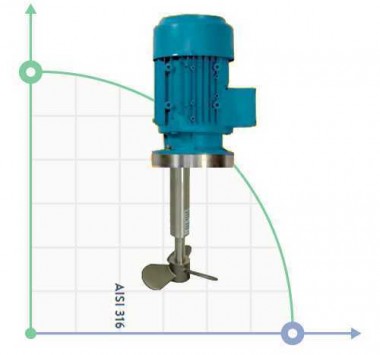

Mixer usage: DRX mixers have a wide range of applications, including homogenization process in wastewater treatment plants, water treatment in: denitrification-maximum allowable flow rate of 150 m3; nitrification - flow rate up to 150 m3; phosphate treatment - flow rate up to 150 m3; pool cooling - flow rate up to 150 M3; coagulation-flow rate up to 150 M3; stormwater treatment - flow rate up to 180 M3; sewer treatment - maximum allowable flow rate of 25 M3. The Prevention of crust formation varies depending on the type of liquid. Preventing ice formation varies depending on the temperature of the liquid. The mixing of chemical liquids varies depending on the type of liquid.

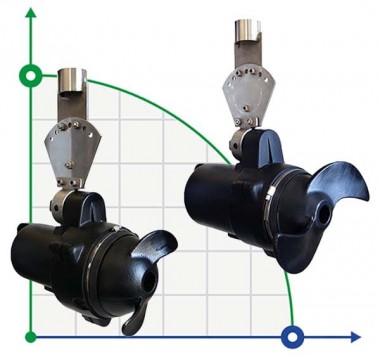

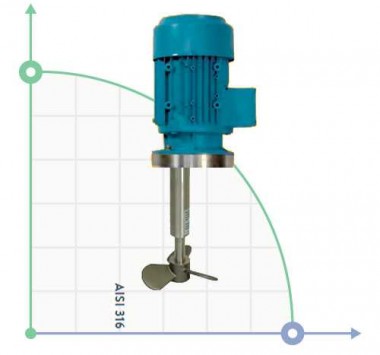

Design features: EN GJL-250 cast iron main components; one mechanical seal and one oil bath cuff seal guarantee perfect performance.

Mounting brackets made of Aisi 416 stainless steel.

Motor: asynchronous 4-pole closed-loop motor; thermal protection integrated in the winding for connection to the corresponding control panel; insulation Class F 155°; protection: IP68; voltage: 220v / 380V ± 5%; frequency 50Hz ± 2%.

Engine cooling: the engine is cooled by the liquid in which the mixer is immersed.

Limits of use: maximum permissible liquid temperature: 40°C when the pump is fully submerged; on request, special version for maintaining liquid temperatures up to 60 ° C with the pump fully connected, maintenance-free S1; maximum immersion depth: 20 m; permissible pH value: 6-10; maximum solid content in the liquid: 10 kg / m3; mixing capacity: 100-150 ML / G; mixing degree: 2.5.

Documentation DRX 200-42/110 submersible mixer

Download instructions, catalog for DRX 200-42/110 submersible mixer