Products from the same category

$28

Pre-order only

$883

Pre-order only

Description

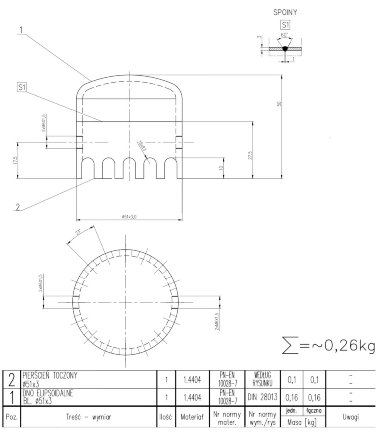

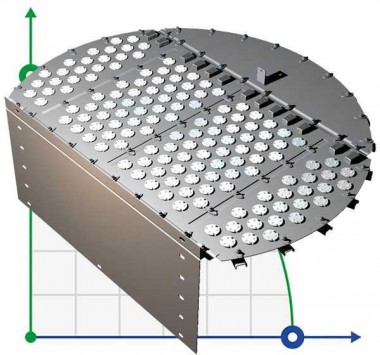

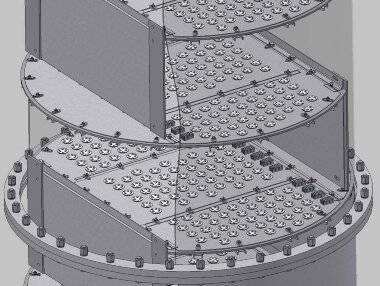

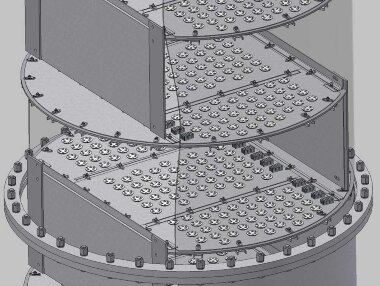

The main component of a column with cap plates is a vertical cylinder, which is completely welded or assembled in separate zones (zergs). In this case, the overflow multi-cap plates are installed at a certain distance from each other. The distance between the plates is determined by the process parameters and the column diameter.

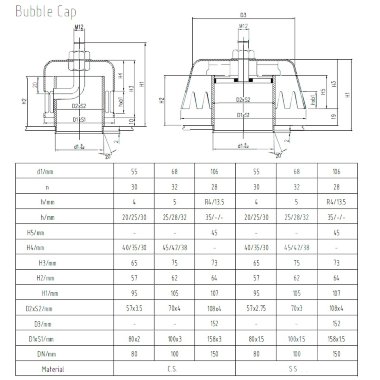

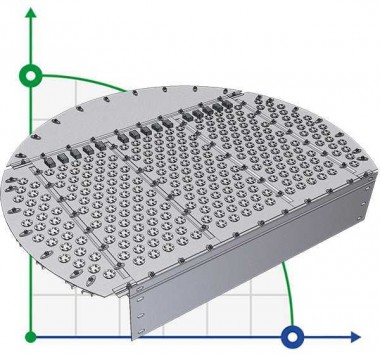

The cap plates consist of a web with a nozzle that is closed with a lid on top. The liquid flows from plate to plate through the overflow, and the level on the plate is set to the upper edge just above the drainage threshold. The lower part of the overflow device is below the liquid level, forming a hydraulic valve that prevents gas from passing through the overflow opening.

The cap is immersed in the liquid at its lower end. The gas enters the space below the cap through the nozzle, passes through the liquid layer and escapes as bubbles from under the cap.