Products from the same category

$2,311

In stock

$3,125

In stock

$4,945

In stock

$4,587

In stock

Description

Thermo-oil pumps are designed to pump heat transfer fluids with temperatures up to 350°C in heat exchange systems without the need for external cooling of the pump.

The pumped liquids must have lubricating properties and be free of solid or abrasive particles, as the drive bearing and mechanical seal are not lubricated by the pumped liquid.

Applications of thermal oil pumps: chemical and pharmaceutical industry, mineral oil, food industry, leather and textile industry, woodworking, paint and varnish industry, construction, tar and bitumen, electrical industry

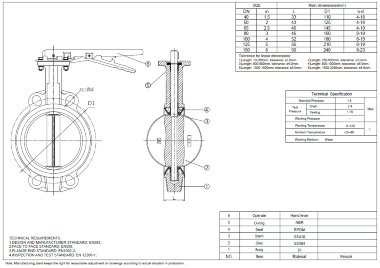

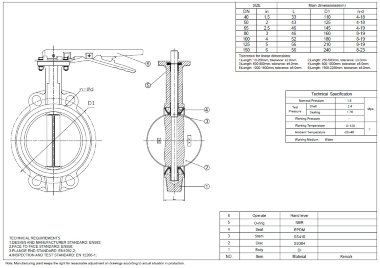

The LQLRY thermal oil pump complies with EN733 (DIN24255).

The unique design of the bearing housing with heat dissipation ensures a reduced temperature on the surfaces of the dynamic seal (or mechanical seal) and the bearings.

These pumps are additionally equipped with a safety seal and a throttle valve upstream of the dynamic seal (or mechanical seal). In the event of a seal failure, this prevents the pumped liquid from escaping in dangerous quantities. With a properly connected drain connection, the safety requirements of DIN 4754 are met in full. (The pumps are fitted with a drain connection to ensure that any leakage past the shaft seal is safely discharged through this connection.)

High temperature casings are fitted wherever possible.

Due to the unique heat dissipation design, no special protective cover is required for the coupling.

Documentation Vertical thermal oil pump LQLRY50-50-210/2-CEX, 12.5 m3/h, 50 m, 5.5 kW, 2900 rpm, Ex

Download instructions, catalog for Vertical thermal oil pump LQLRY50-50-210/2-CEX, 12.5 m3/h, 50 m, 5.5 kW, 2900 rpm, Ex

Also buy with this product