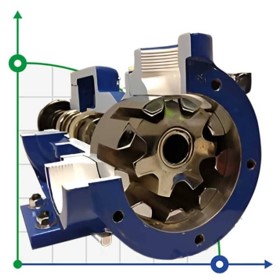

Rotary vane pumps for fuel, oil products

Among the many designs of mechanical volumetric vacuum pumps, the most widespread are vane-rotor units, which ensure the creation of a residual pressure in a sealed working area from 4 x 102 mbar to 5 x 10-4 mbar, that is, in areas of low and medium vacuum, especially in demand in various industrial applications. These pumps are used in the mechanical engineering, woodworking, furniture, chemical, food and processing industries for pumping out air, non-aggressive, non-toxic and explosive gases, as well as vapors and vapor-gas mixtures purified from dripping moisture and mechanical impurities.

The most distinct criterion by which vane-rotor HVs are divided into groups is the presence or absence of vacuum oil in their working chambers. In accordance with these characteristics, they belong to “dry” (in these pumps oil is not used even to lubricate the mechanisms) or “oil-filled” (more often called “oil”) vane-rotor HVs (in them, when the pump is operating, it is “along the way” lubricated mechanisms).

In turn, oil-filled units are divided into two subgroups:

- equipped with an oil separator;

- without oil separator.