Equipment health audit, vibration diagnostics and alignment

An audit of the serviceability of the equipment of an enterprise in which machines and mechanisms with drives are operated consists of the following three stages, namely:

- 1. Vibration diagnostics of drive machines and mechanisms.

- 2. Checking the alignment of drive machines and mechanisms.

- 3. Laser shaft alignment process.

Vibration diagnostics of equipment is one of the methods for checking the reliability and performance of mechanisms, machines, and units, which consists of measuring and analyzing the vibration levels of drive mechanisms and engines during their operation with a load, which allows us to determine what technical condition they are in.

Vibration diagnostics is carried out for engines, gearboxes, fans, turbines, bearing units, compressors, pumps and other equipment.

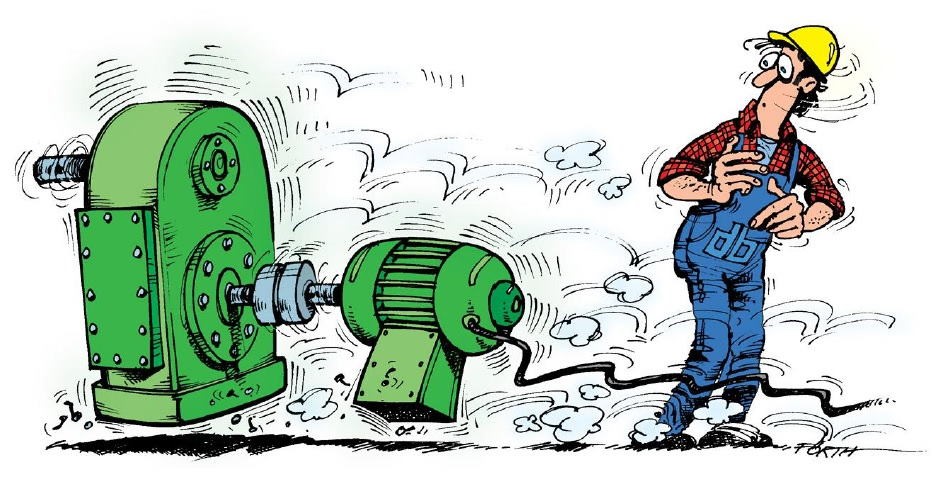

Very often, especially after the installation of high-speed drive machines and mechanisms, during commissioning there is a need for high-precision alignment of equipment. First of all, the alignment of the shafts of the electric motor with the pump, with the compressor, with the fan, with the unit, etc.

Equipment in which the shafts are not aligned is dangerous and in many cases can lead to negative consequences, such as:

- increasing the level of vibration (vertical, horizontal) of the unit;

- destruction of the foundation and fastening of the unit;

- excessive heating of bearings (sliding or ball);

- depressurization of equipment;

- premature failure of the coupling joint, bearing units, mechanical and stuffing box seals;

To do this, it is necessary to timely check the misalignment using high-precision laser alignment of the shafts (alignment) - the process of correcting the position of the axes of the rotating elements of the mechanism relative to each other - in accordance with the necessary standards and tolerances.

Laser alignment devices allow you to relatively quickly and efficiently not only indicate the negative alignment of the machine and drive half-couplings, but also provide the necessary instructions to specialists on what needs to be done to correct it with an accuracy of no more than 0.03 mm.

The laser shaft alignment process is as follows:

Preparation for alignment, collection and analysis of technical information about the equipment, inspection of unit components, fastening to the foundation, the possibility of installing a laser measuring system and the presence of limitations.

Carrying out the necessary measurements of the drive machine to enter information into the device’s memory necessary to calculate the misalignment values of the unit. Determination of real values of misalignment of shafts of mechanisms and machines.

At the end, a general assessment of the measurement results obtained using the instruments and a decision on whether to carry out alignment.

During shaft alignment, the position of the units is adjusted in the vertical and horizontal directions until the values of angular misalignment and parallel displacement are obtained within the required tolerances, which are specified in the operational documentation.

After this, a repeated control measurement is carried out to confirm the result of the unit’s alignment, a form for laser alignment of the unit is drawn up indicating the latest and previous alignment indicators, and if necessary, installation of seals against unauthorized intervention by unqualified personnel.