Products from the same category

Description

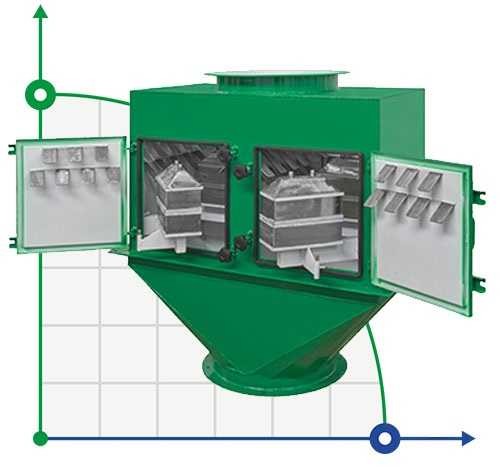

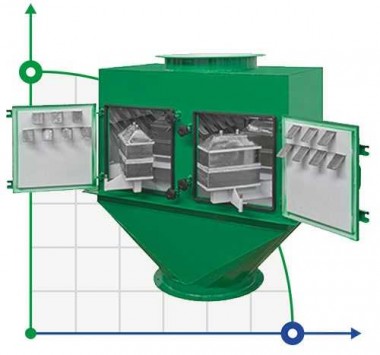

Magnetic separator 30/8-20.008 is used for cleaning bulk materials from ferromagnetic impurities.

Magnetic separators (iron separators) are designed for cleaning bulk products from ferromagnetic impurities. The presence of ferromagnetic impurities in the flow of raw materials and its ingress into the process equipment leads to the failure and breakdown of this equipment, significant production downtime in repair.

It is used in the chemical, petrochemical, food, woodworking, pulp and paper, flour, grain, feed, etc.

The principle of operation is that the initial product with the set capacity is fed to the working area of the separator, where the ferromagnetic impurities settle on the magnetic block located inside the housing. The separator is cleaned manually during the shutdown, and the magnetic block is removed from the housing.

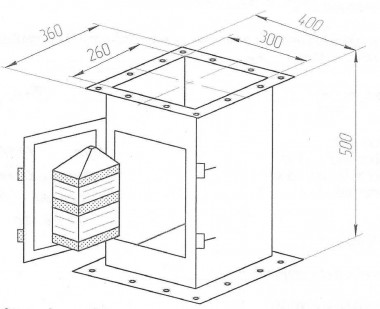

Specifications :

- installation location: vertical;

- capacity: 6 t / h;

- magnetic induction on the surface of the magnetic block at a temperature of 20°C at least 230 MT;

- product temperature: no more than 40°C;

- cleaning of the separator: manual, with stopping the product supply;

- weight: no more than 125 kg.

Good price