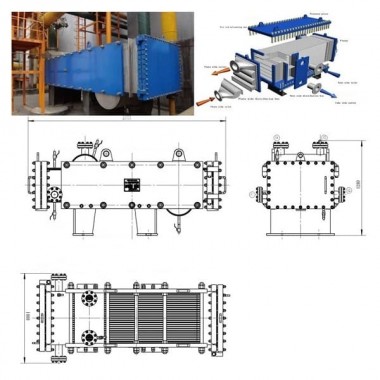

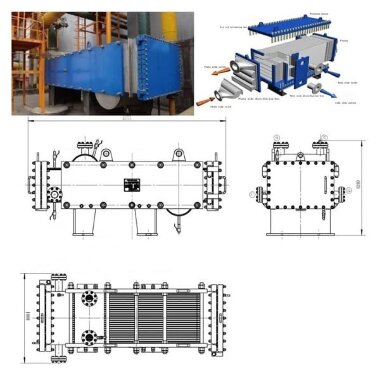

Wide Gap Free Flow Fully Welded Anti-Clogging heat exchangers

Wide Gap Free Flow Fully Welded Anti-Clogging heat exchangers are an innovative device in the field of heat supply equipment. They are able to perform their functions even more efficiently, cope with high temperatures and pressures. Suitable for a wide variety of systems used in working with sugar, bioethanol, cellulose and paper. Also, this type of device can be used in the petrochemical industry and in working with condensers for heat recovery.

What are Wide Gap Free Flow Fully Welded anti-Clogging heat exchangers designed for?

As a rule, heat exchangers of this type are used for working with fibrous substances or liquids with large particles. There are wide gaps between the plates that allow easy passage of liquid between them with minimal contamination.

The design consists of wide and wide-narrow channels, so that the device easily copes with the heating and cooling functions assigned to it. The sleek design ensures that the fibers do not get stuck at the inlet, which ensures safe, efficient and long-term operation of the device without the need for additional cleaning or repair.

Advantages and design features of devices

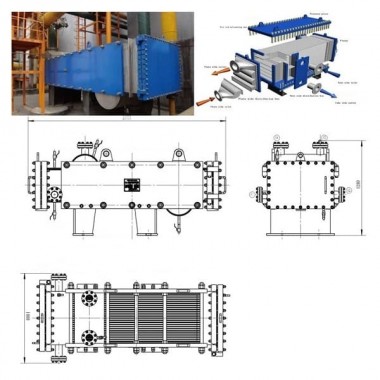

Compared to standard heat exchangers, devices with the Wide Gap Free Flow Fully Welded Anti-Clogging design are significantly more efficient. So, they have an improved flow geometry, which shows the following advantages:

- Small size-allows you to save space, as it takes up only 20% of the floor area and is 80% lighter if it is located in a technological environment;

- High level of heat generation - quickly heats the flow to the desired temperature with minimal loss of efficiency;

- High level of productivity-achieved through an updated design and extended service intervals;

- The ability to easily optimize and adjust the device to different types of systems, as well as quickly adapt to new operating conditions, which can be achieved by changing the order of plates.

If you are not sure which heat exchangers to use, please contact us. Our managers will professionally advise you on which device is suitable in a particular situation, as well as tell you about the advantages and disadvantages of each of them, so that you can make a balanced final decision.