- Home

- Automation of technological processes

- Equipment

- Control and measuring devices

- Flow measurement devices

Gas flow meter Roots

- Medium: free of impurities, no corrosive gases, natural gas, etc.

- Accuracy: ±1.5%, ±1.0%.

- Repeatability: better than 0.1%.

- Measuring gauge: DN25-DN200, can be customized.

- Flow range: 0.5 - 1600 m3/hour.

- Contents of display information: instantaneous flow, accumulated flow, temperature, pressure, etc.

- Connection type: flange connection.

- Power Source: Lithium battery power supply or external 24V DC power supply.

- Output: Pulse output, 4-20mA output, RS-485 COMMUNICATION and GPRS wireless remote data transmission.

- Advantages: measuring head can be rotated 270°, high accuracy and wide measuring range. It can be used with IC card controller or transmitted remotely, which is convenient for commercial settlement.

Operating principle of a Roots gas flow meter

The Gas Roots flow meter is a volumetric flow meter.

As gas passes through the flow meter, the pressure difference created between the inlet and outlet acts on a pair of support wheels connected to high-precision synchronous gears to drive the support wheels.

During this period, the closed space formed between the belt wheel and the inner wall of the housing and the seal is periodically inflated and exhausted by the metering chamber. The speed of the drag wheel is proportional to the volume of gas passing through the flow meter.

The rotation of the wheel is transmitted to a mechanical counter or pulse flow output signal through a magnetic connector to accumulate the volume flowing through the metering cavity to achieve the measurement target.

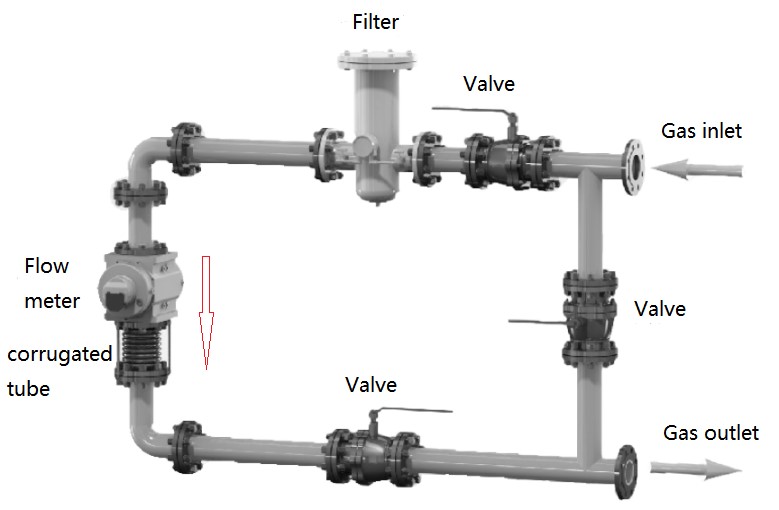

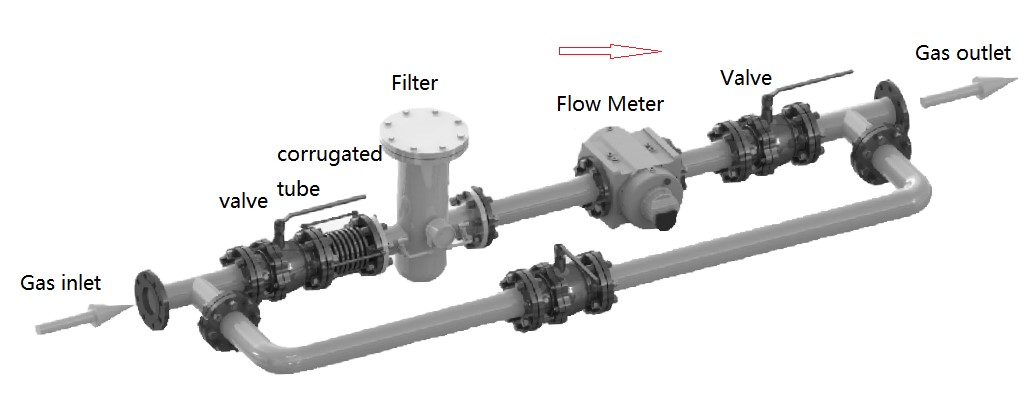

Requirements for installing a gas flow meter

Before installing a flowmeter (especially new or repaired pipeline), the pipeline must be purged to remove impurities such as welding slag and rust.

(1) Vertical installation

With vertical installation, the gas inlet should be from above, and the air flow will go from top to bottom, that is, from top to inside and from bottom to outside. The company recommends that users use a vertical installation as much as possible. The ability of the rotor to self-clean from small parts;

(2) Horizontal installation

When installed horizontally, the axis of the inlet and outlet ends of the flowmeter should not be lower than the axis of the pipeline to prevent gas impurities from being trapped in the flowmeter and affecting normal operation. In this case, the flow meter flange must be directly connected to the filter flange;

(3) Regardless of vertical or horizontal installation, the rotor shaft in the flowmeter must be in a horizontal position.

Features of the Rroots gas meter

- High degree and good repeatability. The internal rotor is precision machined, balanced and tested and rotates without contact. Good lubrication ensures consistent flowmeter accuracy and long service life.

- There is no need for straight pipes before and after the flowmeter, so it can be installed in a narrow environment.

- The initial flow is small and the span factor is wide, suitable for measuring gas flow with large changes.

- The measurement degree is not affected by changes in pressure and flow, with stable performance and long service life.

- Good versatility, all Roots flow sensors can use universal accessories.

- Set up RS-485 communication interface and dedicated IC card hub. It can also form a remote monitoring system for machine data acquisition via GPRS/CDMA, Internet and telephone network. This is convenient for centralized data collection and real-time management.

- It uses floating point calculations and five-segment automatic counter gain correction, as well as self-diagnostic fault and alarm functions.

- The flow value is displayed on site with multiple signal output functions.

- A high-contrast LCD display is used. It can display standard cumulative flow, standard volume flow, volume flow percentage under operating conditions, medium temperature, pressure value and battery consumption percentage.

- With real-time data storage function.

- The degree of protection of the flow meter housing is IP65.

- Explosion protection mark - ExibllCT4.