- Home

- Automation of technological processes

- Equipment

- Control and measuring devices

- Flow measurement devices

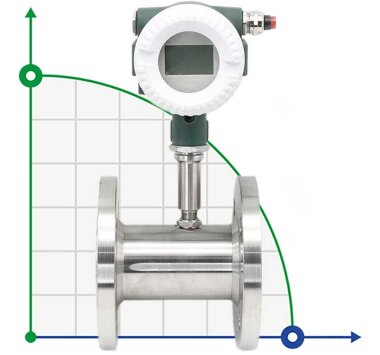

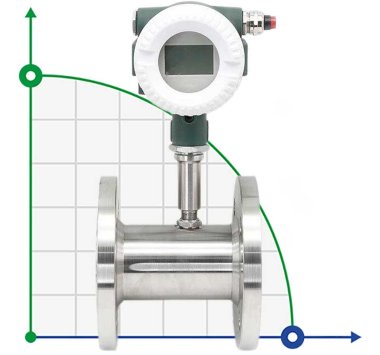

Turbine liquid flow meter

- Medium: liquid without impurities such as fibers, particles, etc.

- Accuracy: gas and steam + - 0.5%, liquid +- 1.0%.

- Repeatability: 0.05%, ±0.2%.

- Measuring range: 0.04-800m3/h.

- Contents of the displayed information: instantaneous flow, accumulated flow.

- Measuring gauge: DN4-DN200.

- Connection type: thread and flange\special can be customized.

- Power supply: lithium battery or external 24V DC power supply.

- Output: Pulse output, 4-20mA output, RS-485 COMMUNICATION and wireless remote data transmission by GPRS, Hart, etc.

- Advantages: high CD accuracy, low cost, ease of installation, good seismic characteristics.

Operating principle of a turbine type flow meter

The working principle of turbine type flow meter, liquid turbine flow meter has small pressure loss, impeller with anti-corrosion function, strong anti-magnetic interference and vibration ability, reliable operation, long service life, durable function of the whole machine, low energy consumption. A liquid turbine flow meter is used to measure total volumetric flow and/or flow rate and has a relatively simple operating principle. As fluid flows through a turbine meter, it impinges on the turbine blades, which rotate freely around an axis along the centerline of the turbine housing. The angular (rotational) speed of the turbine rotor is directly proportional to the speed of the fluid flowing through the turbine. The resulting output is sensed by an electrical sensor(s) mounted on the flow meter body.

Medium to be measured

Fluid flow measurement, instrument range and gauge When measuring the general medium, the full-scale flow of a turbine flow meter can be selected in the measuring fluid flow range of 0.5-12 m/s, and the range is relatively wide. The selected instrument size (gauge) is not necessarily the same as the process piping size and should be determined according to whether the flow measurement range is within the flow rate range. That is, when the pipeline flow rate is too low to meet the flow meter requirements, or when the measurement accuracy cannot be guaranteed at this flow rate, the meter diameter must be reduced so that the pipeline flow rate is high and satisfactory measurement results are obtained.

Installation

1. Installation location

The flow meter must be installed horizontally and the flow direction arrow on the sensor during installation must match the direction of fluid flow.

2. Installation location

The flow meter should operate under the condition that the measured liquid temperature is -20~+120℃ and the ambient relative humidity is not more than 80%. In terms of ease of maintenance, it should be installed in a place where it is easy to disassemble and replace, and avoid pipe vibration or pipe stress. Taking into account the protection of the amplifier, it should be avoided from strong thermal radiation and radioactivity. At the same time, the influence of a strong external electromagnet on the detection coil should be avoided. If this cannot be avoided, a shielding cover should be installed on the sensor amplifier, otherwise the interference will seriously affect the normal operation of the indicator instrument.