- Home

- Automation of technological processes

- Equipment

- Control and measuring devices

- Flow measurement devices

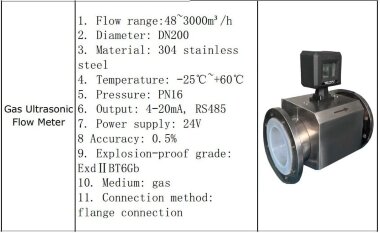

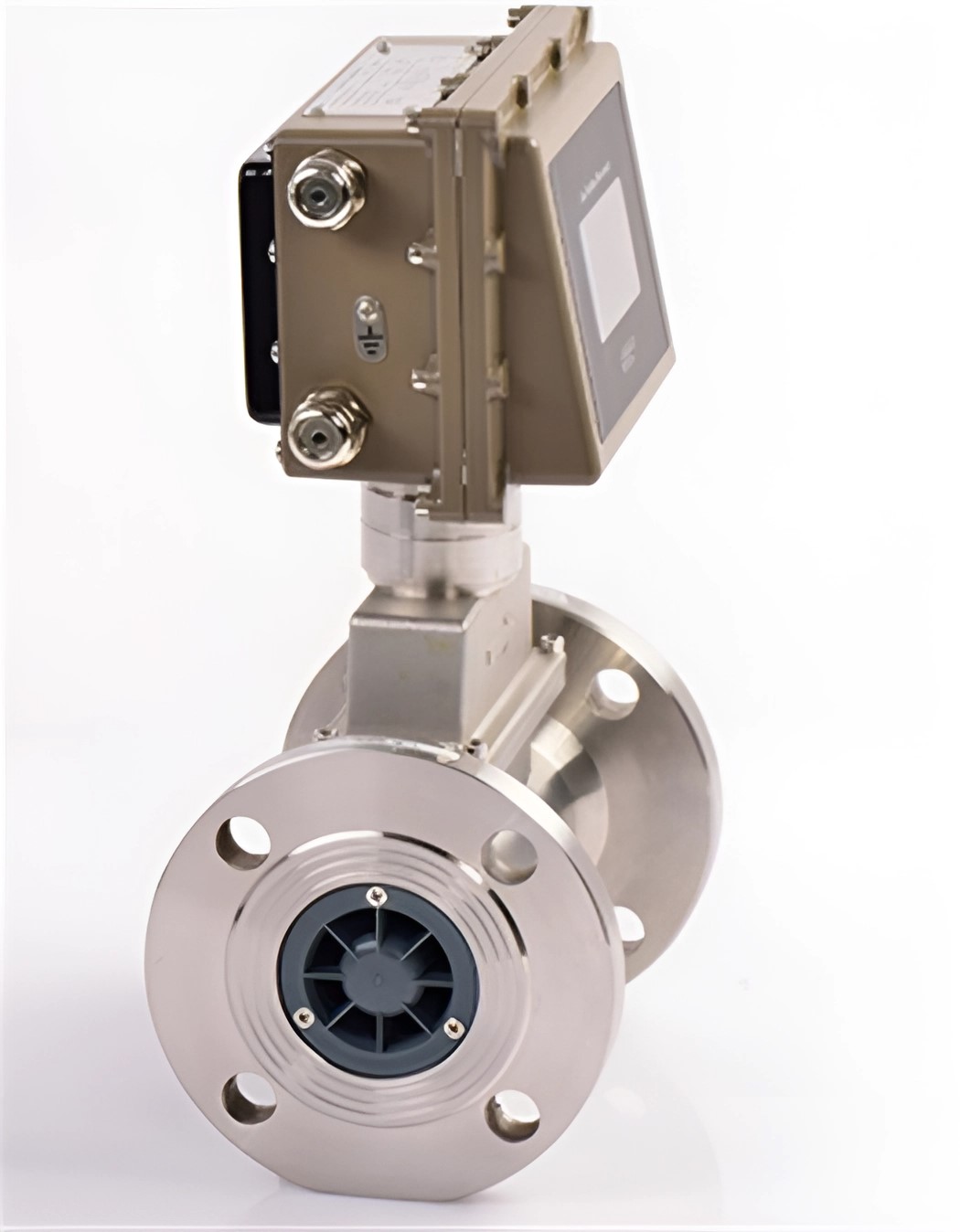

Ultrasonic gas flow meter

- Medium: free of impurities, no corrosive gases, natural gas, etc.

- Accuracy: ±1.5%, ±1.0%.

- Repeatability: better than 0.1%.

- Measuring gauge: DN25-DN200, can be customized.

- Flow range: 1-2000m3/hour.

- Contents of display information: instantaneous flow, accumulated flow, temperature, pressure, etc.

- Connection type: flange connection.

- Power Source: Lithium battery power supply or external 24V DC power supply.

- Output: pulse output, 4-20mA output, RS-485 COMMUNICATION and wireless remote data transfer via GPRS.

- Advantages: The measurement range can include turbine flow meters. Two-channel measurement, high noise immunity. No moving parts, long service life. It can be used with IC card controller or transmitted remotely. Carrying out calculations.

Measuring principle of ultrasonic gas flow meter

An ultrasonic flow meter is implemented by measuring the propagation time of ultrasonic waves in a pipeline. The gas flow rate is determined by the flow rate, the cross-sectional area of the pipe and the Reynolds number. Compact ultrasonic transducers installed in pipelines or flues, respectively upstream and downstream, send and receive encoded ultrasonic signals passing through the gas stream. The flow meter measures the difference in the time of movement of pulses in the direction of flow and against it and, using digital processing methods in combination with modern methods of coding and correlation detection of the signal, calculates the speed and flow rate of the gas flow. This method provides accurate indicators of gas flow rate, independent of external influences.

Application of Ultrasonic Gas Flow Meter

- Gas (coke oven gas, blast furnace gas, converter gas, industrial gas, blue coal gas) and measurement of other gases;

- Gas metering (biogas), biofermentation gas, biomass gas, landfill gas, wastewater treatment plant aeration;

- Gas exhaust measurement, such as flare gas, flue gas, exhaust gas, waste gas, residual gas, etc.;

- Measurement of non-aggressive gases such as air, oxygen, nitrogen, argon, helium, etc.;

- Accounting: natural gas, liquefied petroleum gas, coal bed methane, oil and gas, mine gas, wellhead gas and other gases;

- Measurement of chemical gases such as hydrogen, acetylene and ammonia.

Features and benefits of ultrasonic gas meter

- Suitable for multi-component dosage. Gas flow measurements are not affected by changes in gas composition.

- It can measure small flow and solve the problem of measuring low gas flow.

- The large change factor meets the requirements of high and low flow rate measurement.

- Pulsating flow can be measured.

- It can be measured in both directions.

- Can measure dirty gas containing impurities and moisture.

- Corrosion resistant, can measure the flow of corrosive gas.

- It can be used online and maintained online.

- The flow meter has no moving parts. No pressure loss, reduced maintenance costs.

- Made of metal, the transducer is resistant to dirt and corrosion. Thanks to its unique algorithm, it can provide gas flow measurement in polluted environments.

- Supports intelligent alarms such as pressure, temperature, flow and ultrasonic signals. It can realize early warning of ultrasonic transducer before maintenance is required. Reduce maintenance frequency. Reduce maintenance costs.

- Visual display of the waveform of the instrument interface based on the menu. The device is easy to use and debug.