Dryers, granulators

Types of dryers and their designs

Therefore, artificial drying of materials is carried out in special devices - dryers, in which the drying agent that after absorbing moisture vapor, it is removed artificially: with the help of fans, injectors, exhaust pipes and other devices.

In practice, there are a large number of different types of dryers, both by design and by the method of supplying heat to the material being dried. Depending on the method of supplying heat to evaporate the liquid and the method of removing moisture, we already know that the following drying methods are distinguished: gas (convective) drying, contact (conductive) drying, radiation drying, dielectric drying, sublimation drying, combined drying.

By design, the following types of dryers are the most common:

- chamber;

- tunnel;

- mines;

- belt dryers (single and multi-belt, shelf and loop);

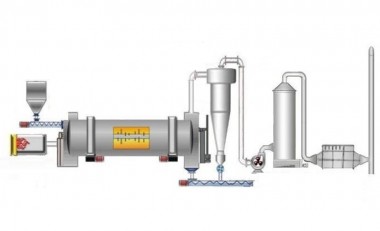

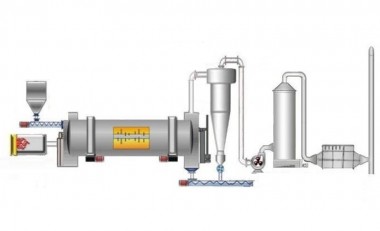

- drum;

- cylindrical;

- fluidized bed dryers, etc.

These types of dryers, in turn, differ in a number of features:

- according to the principle of action (periodic and continuous);

- by the amount of pressure in the drying chamber (atmospheric and vacuum);

- by transport devices (carts, carts, conveyors, etc.)

For example, in convective dryers, which are very widely used in technology, the material being dried can be in a stationary or moving dense layer (drying in tunnel, chamber, belt, etc. dryers) or in a suspended layer or semi-weighted state (drying in drum dryers, shaft dryers, pipe dryers, fluidized bed and vibrating bed dryers, etc.). So, convective dryers are the most common in manufacturing processes. Let's consider some representatives of these dryers.