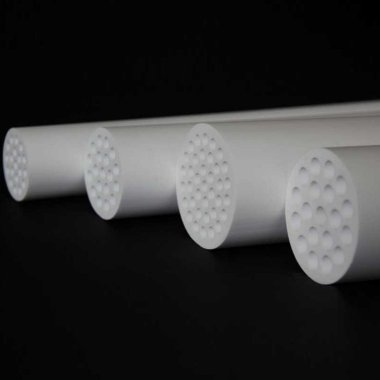

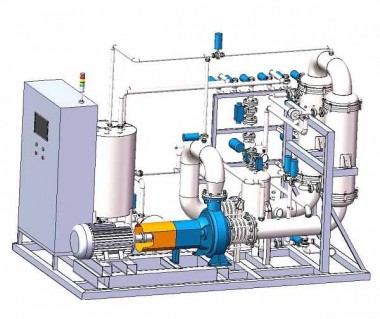

Filtration units

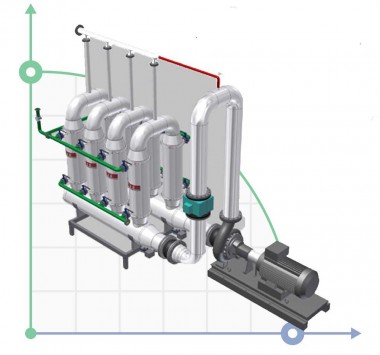

Filtration units are special devices that allow using membranes to filter liquids and separate them at the molecular or ionic level into two streams. The size of the particles subjected to the filtering process may be less than 10 µm. In this case, two equal flows are obtained, which are formed according to the previously specified system capabilities. The streams are characterized by the desired concentrate and residual filtrate. Depending on the situations, the chemical and physical properties of the solutions can be adjusted by the settings of the filtration units.

Areas of use of filtration plants

Filtration units are predominantly used in industry to separate a liquid into two equal streams. It could be:

- food industry;

- oil refining industry;

- pharmaceuticals;

- cosmetic industry;

- petrochemical industry.

The plants differ in the types of membrane processes, which allows the use of different equipment for greater efficiency. However, such installations can be used in any projects where it is necessary to ensure normal filtration of solutions.

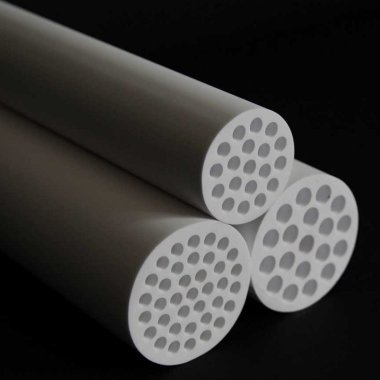

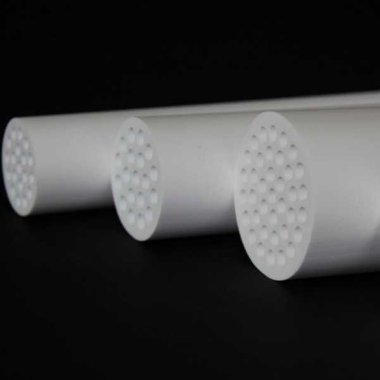

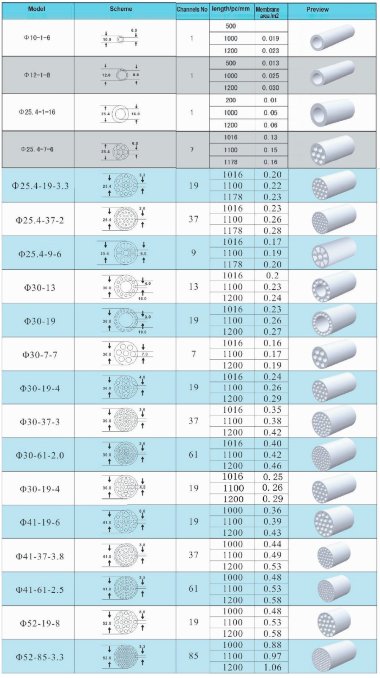

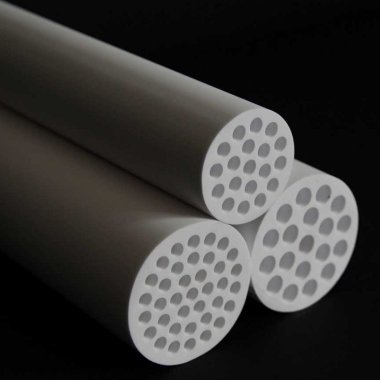

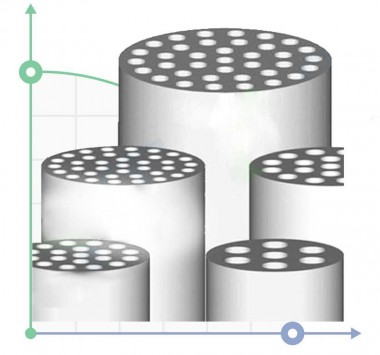

Types of filtration plants

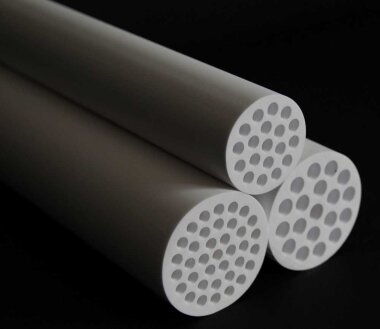

Filtration units are divided depending on the particles that they are able to pass or not pass. The main distinguishing characteristic is precisely the diameter of the trapped particles. Accordingly, there are four main types of filtration plants:

- Microfiltration plant. Focuses on large particles ranging in size from 0.05 to 10 microns. Suitable for use in the food industry, in particular the dairy industry, can be used to remove microorganisms from the solution.

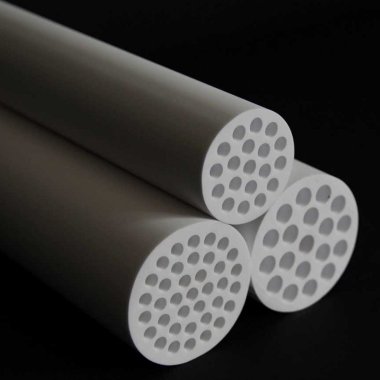

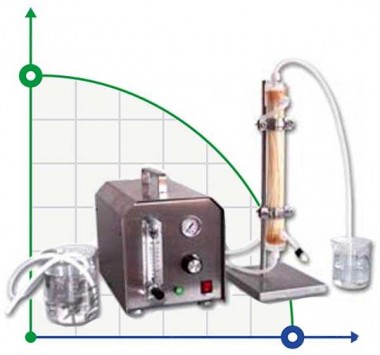

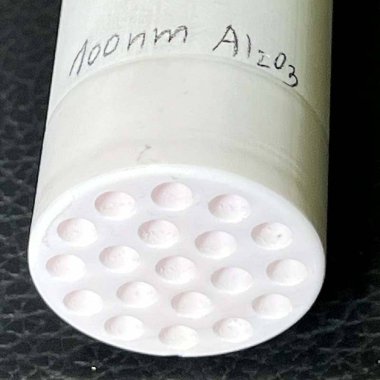

- Ultrafiltration plant. Captures particles as small as 0.001 µm. The use of such an installation can significantly reduce the use of energy and other resources, which is important for large-scale production.

- nanofiltration plant. Works with particles with a diameter from 0.0005 to 0.001 microns.

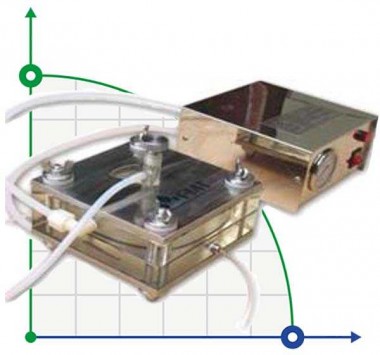

- Reverse osmosis installation. Helps with particles smaller than 0.0005 µm.

Each of these types of installations is distinguished by quality and reliability. Using specialized professional filtration units, it is possible to correctly separate specific elements in the solution, regulate the pressure in the system, and ensure that the content of the elements is acceptable for the project.