The use of heat recovery plays an important role in the technological processes of the alcohol industry.

The engineering company "BTS-Engineering" offers innovative solutions to reduce the consumption of process heat in distilleries.

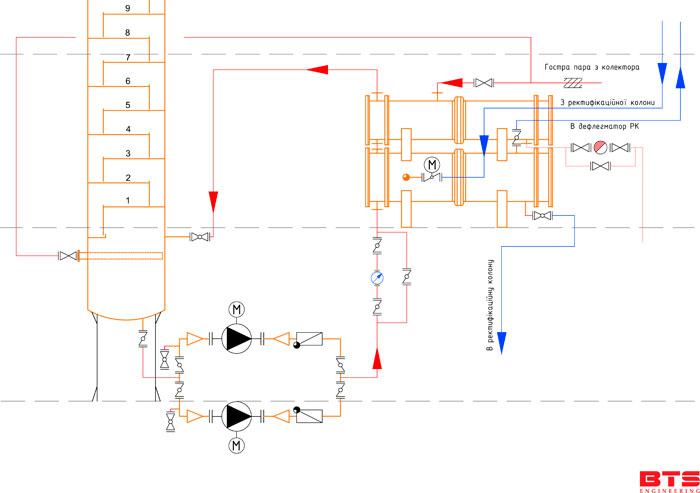

For example, a variant of the layout of equipment for "heating" the brew (distillation) columns (BC) with alcohol-water vapors of the rectification column (RC). The scheme works as follows: alcohol-water vapors from the RC are fed into the inter-tube space of the recuperative boiler BC. The distillery dreg of the cubic part of BC circulation pump first served in the tube space of the recuperative boiler of BC, then in the piping of the boiler steam beer columns were further back in the cube beer columns were for, respectively, heating the stillage to the required temperature and for hydro-alcoholic vapours cooling (condensation) of RC. The amount of pumped distillery dreg (multiplicity) is selected in such a way as to ensure maximum heat transfer (up to 95%) from alcoholic vapors to distillery dreg. The hot steam boiler is installed for force majeure and commissioning. Condensate of alcohol-water vapors (phlegm) is directed to the upper part of the RC.