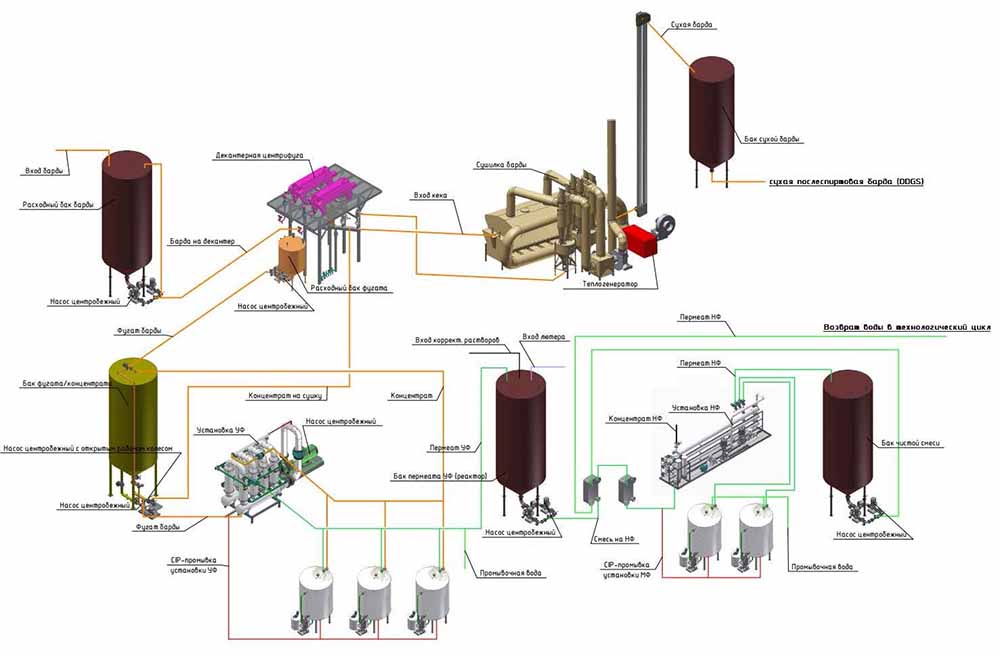

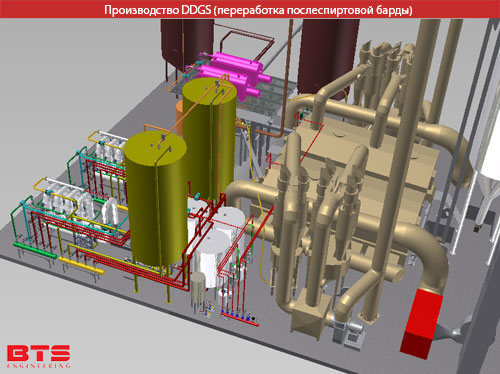

The process of the distillery dreg processing

Distillery dreg contains about 6-9% of dry substances, depending on the quality of raw materials supplied to the technology. The raw protein, nitrogen-free extractives, fat, fiber, ash, vitamins and trace elements, included in the composition of grain raw materials passes in distillery dreg. Using the distillery dreg in liquid form is not always rational due to storage problems – the proteins that make up its composition begin to decompose after a short time, and its transportation over long distances is also not economically profitable. In order to make full use of distillery dreg as a highly nutritious feed, its multi-stage processing is proposed to obtain a line of commercial products used as feed for farm animals and additives to concentrated feeds.

|

|

The distillery dreg is fed to a decanter (horizontal centrifuge), where it is divided into a solid fraction-cake (40% of absolutely dry substances, then-ADS) and a liquid-fugate (5.1% of ADS). Cake can be released as a commercial product, but its storage time is limited to 12 hours, for this reason, it is more effective to dry it in order to obtain DDGS. Fugate, for further utilization and improvement of its quality as a commercial product, is condensed at the ultrafiltration unit until another commercial product is obtained –concentrate (20 ... 23% of ADS). It is possible to sell the concentrate for livestock feed as an independent commercial product, but in order to improve the nutritional qualities of protein vitamin concentrate, the concentrate is mixed with cake and dried.