BIOETHANOL

Turnkey construction of bioethanol plant.

On 19th of June 2012 the Verkhovna Rada of Ukraine passed the draft bill No 10572-1 “About Making Amendments to Some Acts of Ukraine Towards Production and Usage of Motor Fuels Containing Biocomponents” in reference to bioethanol additives in petrol. Particularly, the document has determined that permissible content of bioethanol in petrol produced and realized in the territory of Ukraine, will equal to not less than 5% in 2013, in 2014-2015 normative content of biocomponents in motor fuels shall reach not less than 5%, by 2016 – not less than 7%.

The adoption of the above mentioned document was aimed at reducing dependence of Ukrainian fuel market on energy import as well as at realization of Kyoto Protocol mechanisms to decrease CO2 emissions to the atmosphere.

In order to ensure 5% content of bioethanol in petrol, Ukraine needs 320 millions of liters of ethanol per year. Presumably, nearly 70 millions of liters of bioethanol will be produced by the end of 2013.

Feasibility Study and Calculations

Our company can perform feasibility study of building or reconstruction of bioethanol plant; develop technical assignment, considering the following:

- geographic location of the probable building project;

- choice, price determination, raw materials provision;

- complex raw material processing;

- advanced treatment process of starch-and sugar-containing raw materials;

- automatic process control system;

- minimal utility consumption with possible diversification of purchased organic fuel;

- optimal consumption of process water and minimal environmental impact.

Project and Engineering Services

- In optimal short terms, "BTS-ENGINEERING" can implement projects, in accurate accordance with the current norms regulating performing works on construction and process engineering.

- "BTS-ENGINEERING" possesses advanced technologies in the field of distillation and rectification, heat-power industry, energy saving, heat and mass transfer processes and membrane technologies including technologies on complex processing of starch containing raw materials.

- On the basis of membrane equipment and technologies of micro-, ultra- and nanofiltration for separation and concentration of mixtures, aimed at obtaining valuable components in production of ethanol, biofuel, plant oil and starch, "BTS-ENGINEERING" can provide full and non-waste wholesome production.

- Moreover, "BTS-ENGINEERING" provides software maintenance of all automatic control processes of production.

- Furthermore, we can also provide additional service.

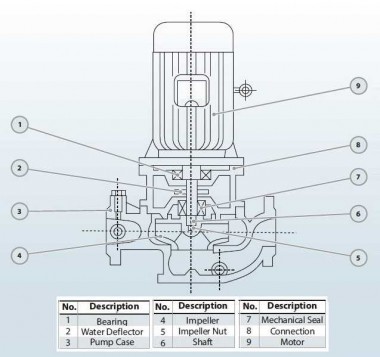

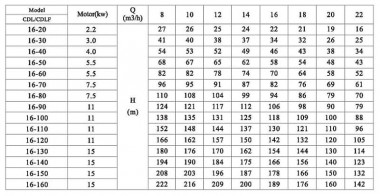

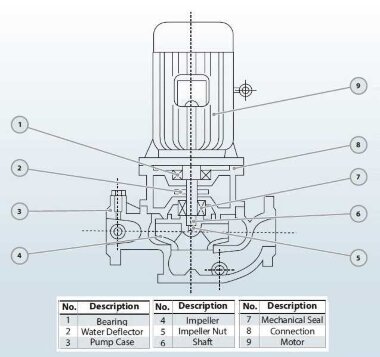

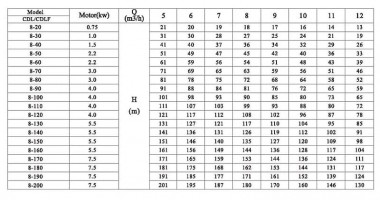

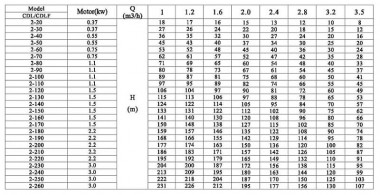

Equipment Supply and Installation Supervision

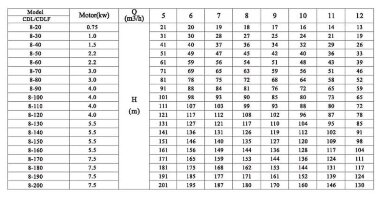

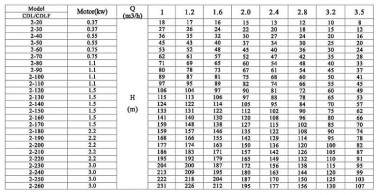

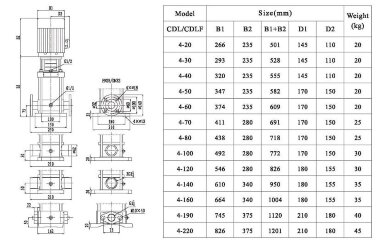

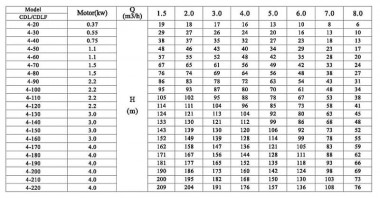

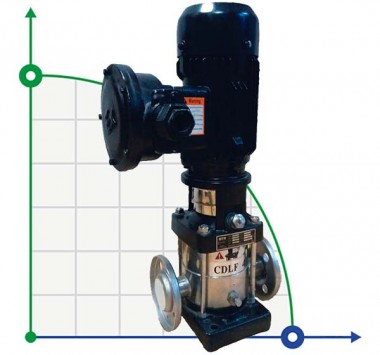

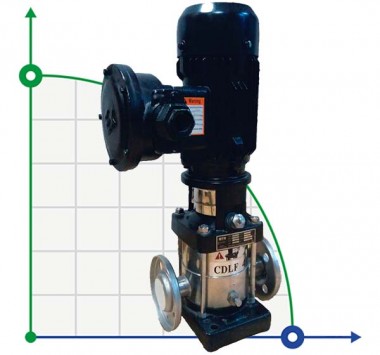

Thanks to cooperation with many Ukrainian, European and Chinese manufacturers, we are able to select and supply equipment for the project installation of bioethanol plant as well as complex processing plant of starch containing raw materials. Besides, additional services are provided:

- development of design solutions;

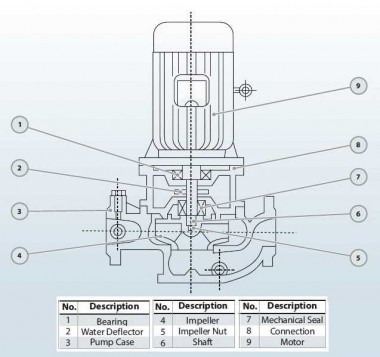

- installation (supervision installation) of equipment for distillation, rectification, dehydration as well as milling equipment;

- automation;

- adjustment and putting into operation.

After commissioning, all kinds of equipment supplied by our company are provided with guarantee and maintenance service. Selection of equipment and optimum alternative of the order, delivery, installation and service are to be agreed with customer.

Start-Up and Commissioning

After all installation and construction works of the plant are performed, we take the plant (operating

department) into operation, perform commissioning works aimed at adjusting the installed equipment and

checking of system functioning as a whole.

The following stage is support and personnel training by

our highly qualified employees for further lean functioning of the main and additional production

processes.

As a result, workable network and competent personnel fully ready for operation are at customer’s disposal.