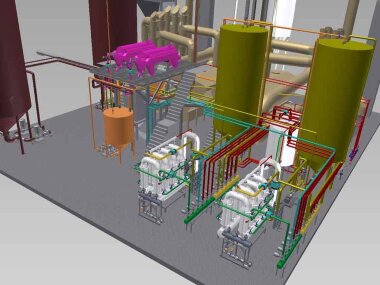

Designing a distillery 15000-20000, 40000 dal / doba

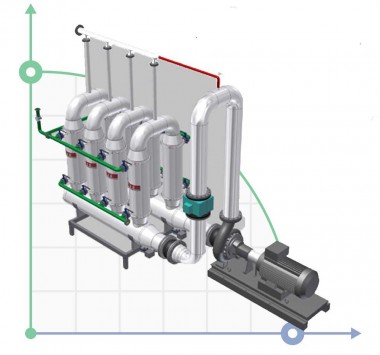

As raw materials for plants with a capacity of 15000-20000 dal/day (40000-53000 tons/year), both starch-containing raw materials (grain, flour) and sugar-containing raw materials (beet molasses, sugar juice, sugar cane, sugar beet, etc.) can act as raw materials. It is possible to produce rectified and dehydrated ethanol separately, or in a percentage (for example, 25% rectified and 75% dehydrated). Complex processing of starch-containing raw materials is recommended. A full cycle of processing with the use of recuperative and recycling cycles is mandatory. The number of branches is from 10 to 11.

The general production technology and the number of branches are given here.

Supply of technology and equipment for the construction of a plant for the production of ethanol from grain raw materials, with a capacity of 100,000 tons / year.

The hourly productivity of the equipment of department 01 should ensure the acceptance of the required amount of grain, taking into account the coefficients of hourly and daily unevenness, and be AT LEAST 150.0 ... 200.0 tons, and department 02-cleaning and processing/drying of grain and its storage for 0.5 ... 12 months, depending on local conditions.

For unloading on-board vehicles, car dumpers are used. Unloading of grain from dump trucks is carried out by gravity into the receiving bunkers. All grain entering the plant with a more normalized clogging should be cleaned on grain cleaning machines to conditions that meet the intended purpose.

Grain is distributed in warehouses STRICTLY according to crops and quality characteristics. The capacity of an elevator or a warehouse for floor storage of grain should be AT LEAST 30 ... 40 thousand tons.

2.1.4. Department 04 - department of boiling and saccharification The batch is pumped from department 03 to department 04, where in hydrofermentation treatment devices (GDFO), under the action of enzyme preparations, both introduced into the batch and additionally introduced into the GDFO, the batch is liquefied and saccharified to form a wort.

The finished wort is sent for fermentation to the department 05-yeast fermentation department, part of the wort is sent for the cultivation of industrial yeast.

- When implementing the project, the Contractor can provide the following engineering services:

- development of technical specifications for the project implementation;

- development of the technological part of the project and the automated control system project;

- assignment of tasks to the local general designer for the development of general construction parts of the project (architectural and construction part, concrete, reinforced concrete and metal structures; general plan and transport; heating, ventilation and heat supply; water supply and sewerage; technological cold supply; technological air supply; electric lighting and power electrical equipment);

- issuance of concepts of technical requirements for the implementation of special sections of the project (fire-fighting automation and fire extinguishing; lightning protection; protection from static electricity; anti-corrosion protection; environmental sections of the project);

- implementation of the author's supervision during the design;

- development of questionnaires and drawings of general types of non-standardized equipment for the technological part of the project for placing orders for its manufacture;

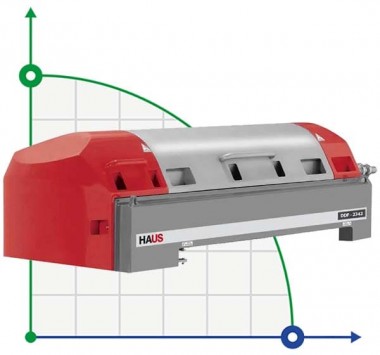

- delivery of specialized technological equipment;

- performance of author's supervision at the stage of equipment manufacturing and construction and installation works-chief supervision;

- chief-adjustment of technological equipment, technological systems and cycles;

- staff training