Equipment for distillation and rectification, recovery

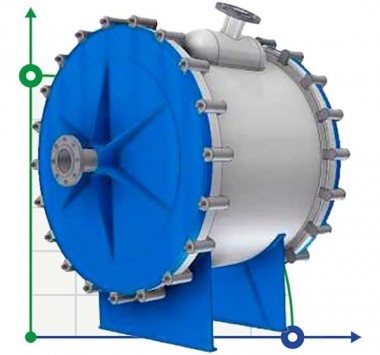

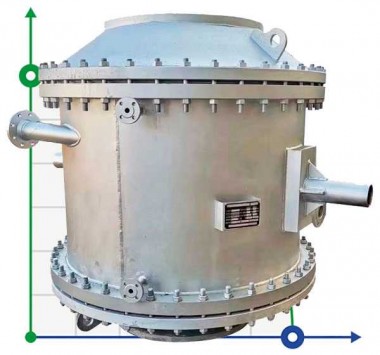

The main source of heat consumption at distilleries is the distillery unit. To reduce heat consumption in the process of ethanol production, it becomes necessary to use regenerative cycles: from the simplest-heating/cooling of intermediates, to heating due to the recovery of individual plants in the process of the brew-purification. BTS Engineering company offers to heat individual columns by heat recovery.

Let's consider an example of the energy costs (acute steam) of the brew and distillation columns at the 3000 dal plant.

The scheme of work is shown in Fig. No. 1

The total consumption of energy resources by two columns is: heat energy in the form of hot steam 46 kg/dal; cold in the form of recycled water 42 kW/dal.

Working with the use of a recuperative scheme (using secondary heat) allows you to save thermal energy in the form of hot steam for heating the brew column and part of the energy for cooling the distillation column.

- The total consumption of energy resources by two columns in the recuperative scheme is:

- thermal energy in the form of acute steam 26 kg / dal;

- cold in the form of recycled water 26 kW / dal.

- That is, the savings only on the use of recuperation on the bundle of the Distillation column-the Brew column is:

- thermal energy in the form of hot steam 20 kg / dal;

- cold in the form of recycled water 16 kW / dal.

Application of recuperation on six columns of brew-purification unit 3000

The total consumption of hot steam of a six-column of brew-purification unit when working under atmospheric pressure is from 60-68 kg / dal.

The consumption of a six-column of brew-purification unit when working under excessive pressure and vacuum (using recuperation) is 30-34 kg / dal.

When implementing an energy-saving scheme at a plant with a capacity of 3000 dal / day, the daily savings amount to 102 tons of hot steam/ day, which in terms of natural gas is 8160 m3 / day

Stable alcohol quality indicators.

Reduction of steam consumption by 2 times.

Reducing greenhouse gas emissions

An example of using column heating with regenerative heat is given here.