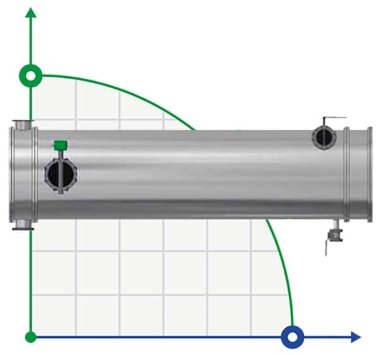

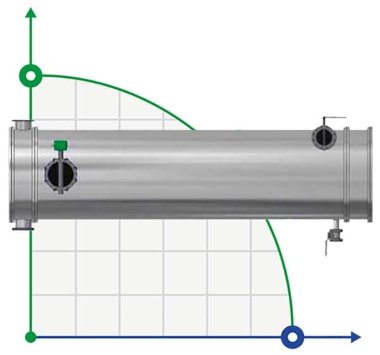

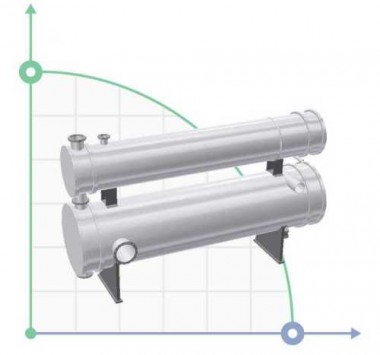

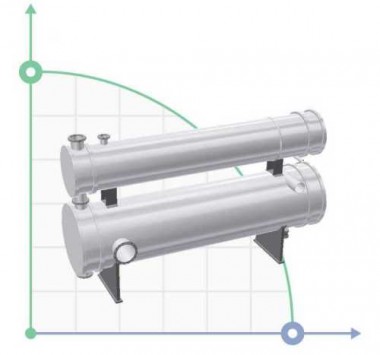

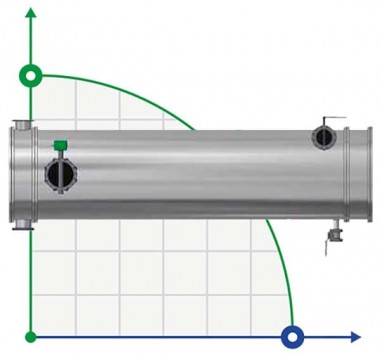

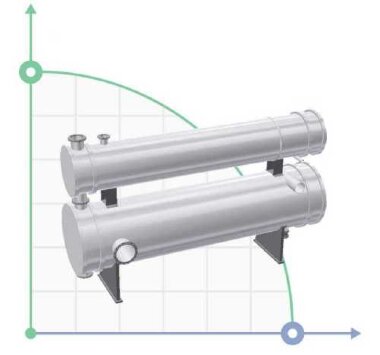

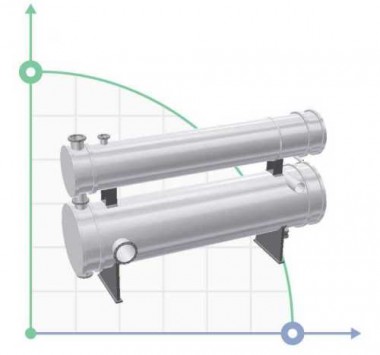

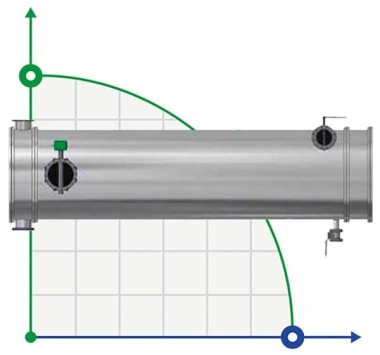

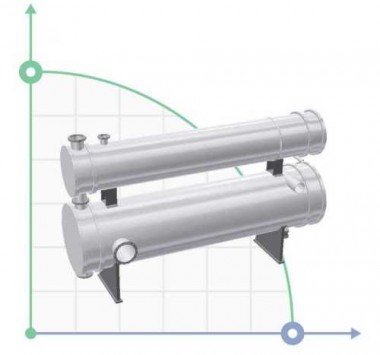

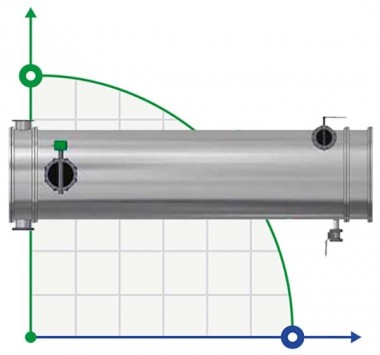

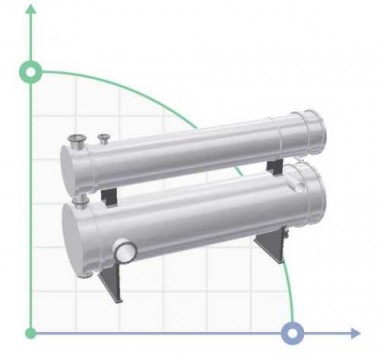

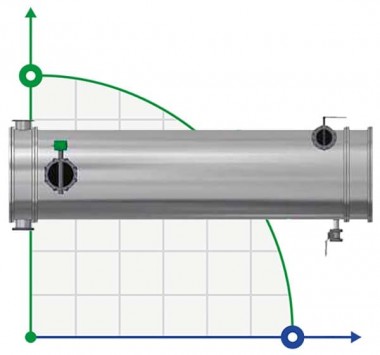

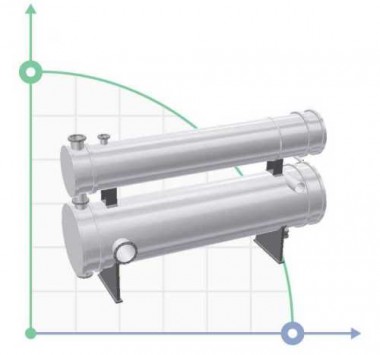

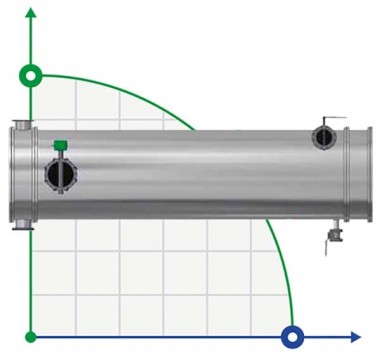

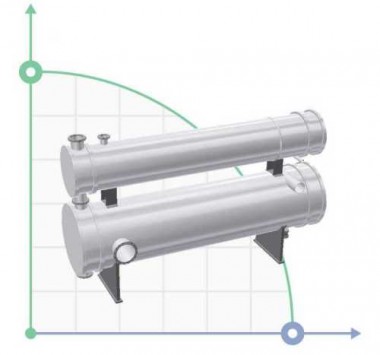

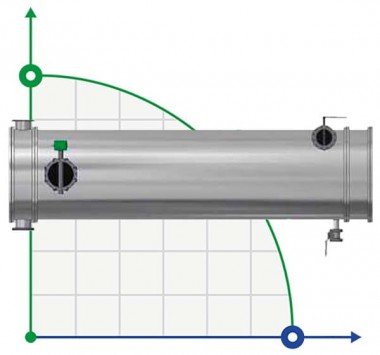

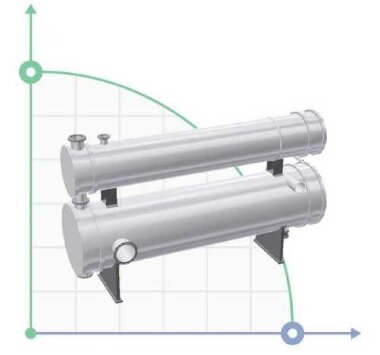

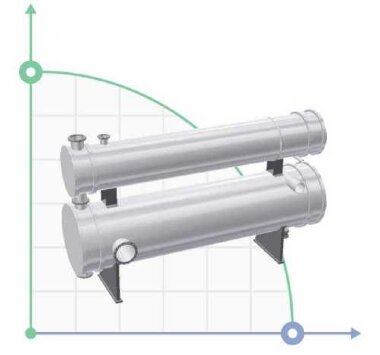

Shell-tube heat exchangers

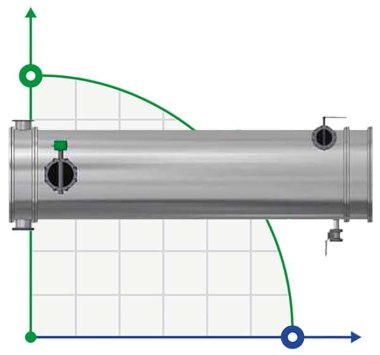

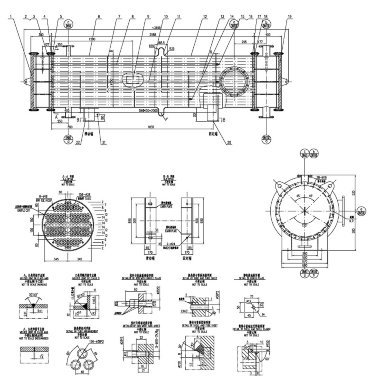

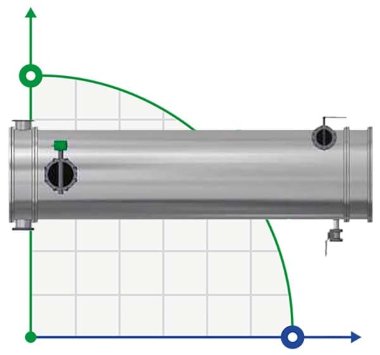

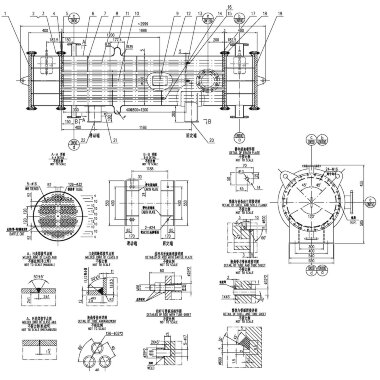

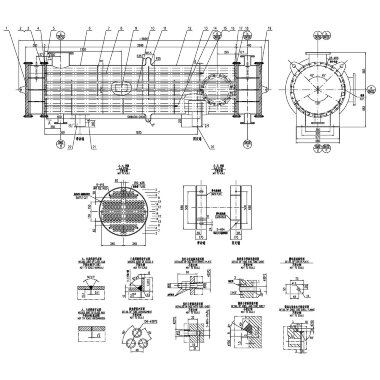

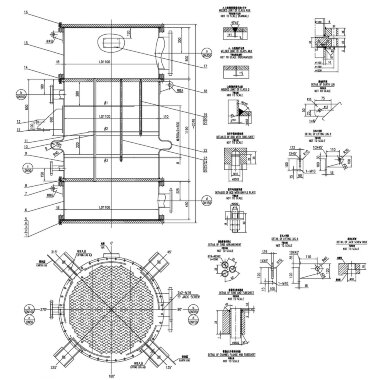

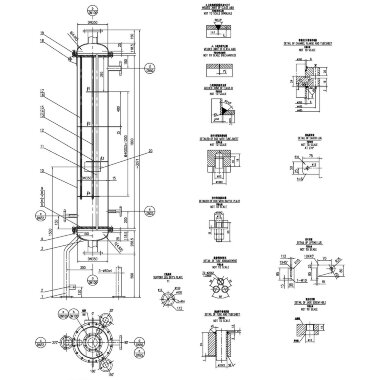

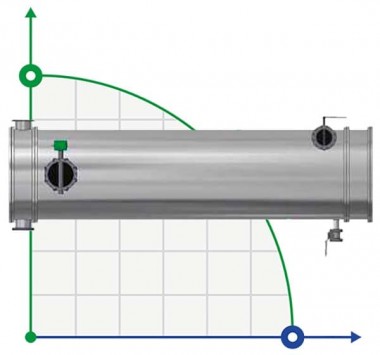

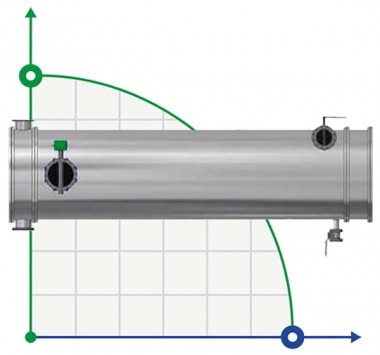

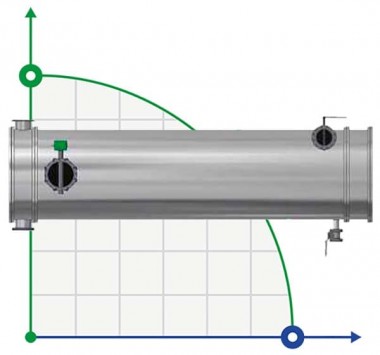

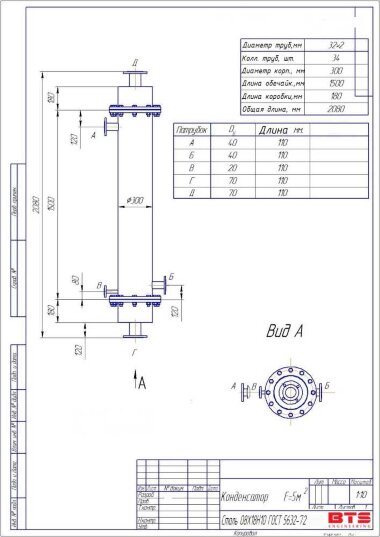

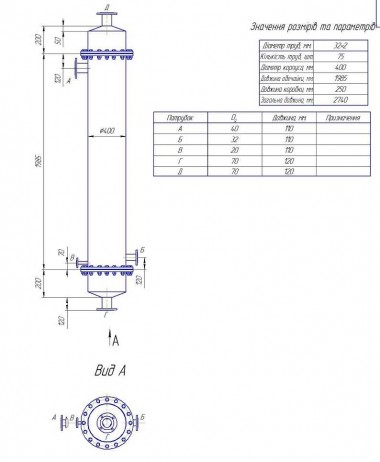

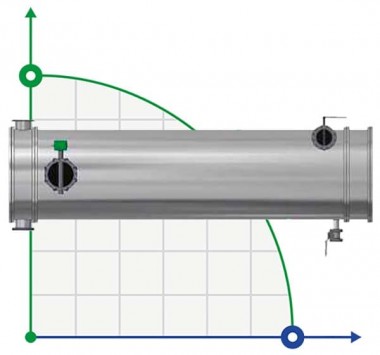

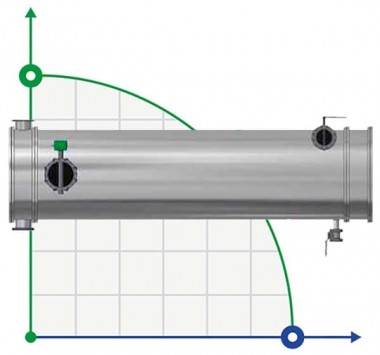

The shell-and-tube heat exchanger is a bundle of tubes that are located in their chamber and fixed to the grid and wrapped in a shell (casing). The tubes are connected to each other either by pipes, or there are also an entrance and exit to the chamber, a condensate outlet, and partitions.

The principle of operation of a shell-and-tube heat exchanger is to transfer heat in the space between the shells, which move media with different temperatures.

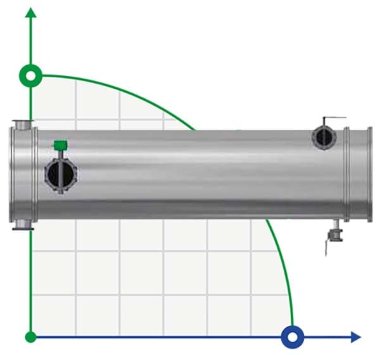

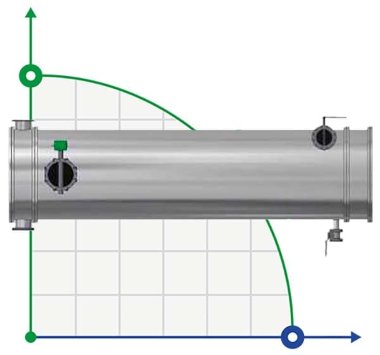

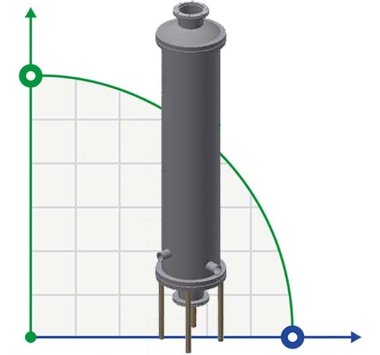

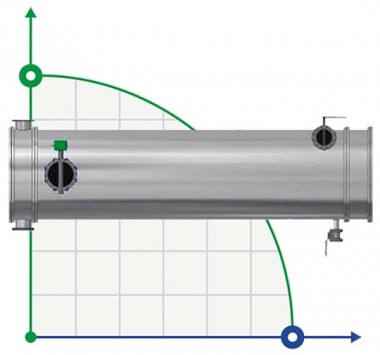

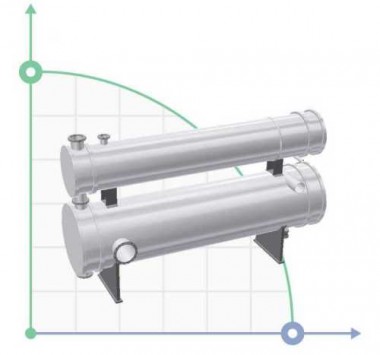

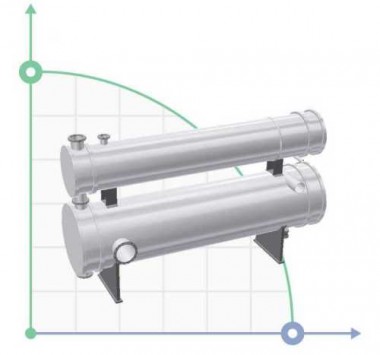

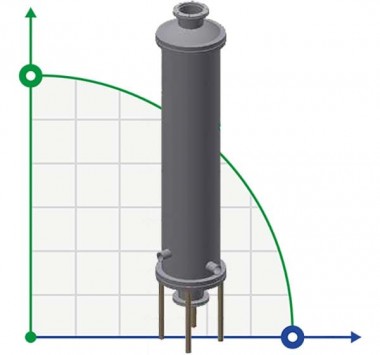

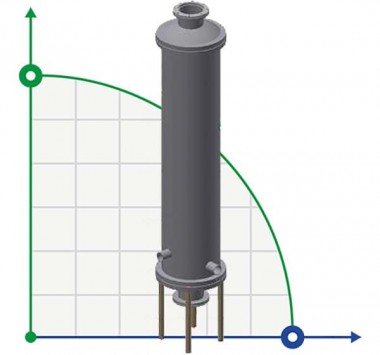

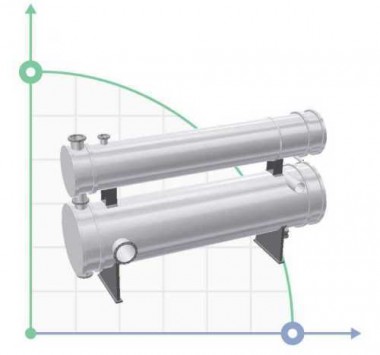

The shell-and-tube heat exchangers have various designs and can be single - or multi-pass (by the number of strokes); direct-flow, counter-current or cross-flow (in the direction of media movement); horizontal, vertical or inclined (by spatial arrangement).

In shell-and-tube heat exchangers, pipes can be attached to a board or grid by welding the pipe, fixing it in flared niches, using bolts to the flanges, soldering, or those that have seals (seals) in the fastener design.