Automatic Control System of Yeast Generation and F

Purpose of APC

Automatic process control system (APCS) of pretreatment section is designed for

reaching high efficiency of process equipment operation by following process procedures, improving end product

quality and reducing its prime cost.

Main Operation Modes

There are three main operation modes of APCS:

- Manual operation mode;

- Automatic operation mode;

- Remote operation mode.

Manual operation mode of APCS - the operator directly controls the controller position (judging from the actuator status) based on the real-time control data being input by the input hardware at the operator's station.

Automatic operation mode of APCS - the operator controls and monitors the way the process equipment being operated automatically works (including that under regulator control), and the way the process goes. The set mode maintanance is performed by a complex of system hardware and software (CSHS) either automatically or under control of the upper level control system.

Remote operation mode of APCS - from the place of operator's control of the system, the operator forms instructions and tasks required for stabilizing or changing parameter of process mode as well as for preventing and localizing accidents and emergency situations. Besides, the operator controls and monitors operation of process equipment and the way the process goes.

Screenshot of «BSS Cross-Control» software

Hardware and Software Complex of APCS

The hardware and software complex of APCS comprises the

following:

- programmable logic controller (PLC);

- personal computer (PC) as operator's station with installed Linux OpenSuse operating system and BSS Cross-Control SCADA set;

- PLC application software;

- application software of the operator's station;

- application software of the data server;

- sensors and primary converters of process parameters control and major equipment condition;

- actuators of regulators.

Output signals of sensors and primary transducers of process parameters refer, as a rule, to continuous electrical

signals of direct current 4-20 mA.

Output signals of sensors for major equipment condition refer to electrical

discrete-time signals which equal to 24V or ~ 220V.

Output signals of the controller for actuators control

refer to continuous electrical signals of continuous current 4-20 mA.

Output signals of actuator control refer

to continuous electrical signals which equal to 24V or electrical discrete-time signals = 24V or ~

220V.

Network communication is accomplished by using standard TCP/IP protocol.

Data exchange between the

system components is performed automatically.

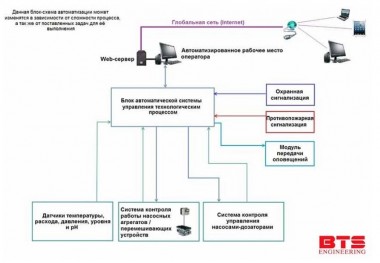

Interconnections of APCS

APCS interconnections work as follows:

- Current (4 ÷ 20mА or discrete) signal of the sensor is transmitted to programmable logic controller (PLC) of the section through the wire line;

- According to the set algorithms, PLC processes the data signal which is transmitted to automated workstation (AWS) of the operator; the signal contains recommendations, made based on the set algorithms, about the impact on the actuator. If operator makes no changes in algorithms, the control signal is transmitted to the actuator. If the operator decides to make some changes in the algorithm, PLC forms the control signal which depends only on the operator's decision;

- Actuator receives and performs current control (4 ÷ 20mА or discrete) signal. Actuator reports PLC on the signal performing;

- System is ready for a new cycle of instruction execution.

In cases provided within the control program, according to the set algorithms, APCS conducts survey of sensors and actuators informing the operator about their status. For safety reasons, in the event of emergency, transition of mechanisms to the state of “EMERGENCY” is recorded by the system, is archived, and after that the message with description of the reason is displayed.

Schematic diagram of automatic process control system of pretreatment section