Our company supplies vacuum pumps for aggressive media made of AISI 304 and AISI 316 stainless steel.

They are designed for working with aggressive gases and liquids and are used in the oil, gas, and chemical industries.

Read more →

Our company presents a line of water ring vacuum pumps of the 2BV series

Lower power consumption, higher efficiency

Stainless steel impeller

Stable vacuum thanks to the design

The body and parts are made on a pressure casting machine

The body material is made of corrosion-resistant cast...

Read more →

Irregular packings have been successfully used as an efficient and cost-effective means of improving column performance and efficiency for several decades.

Advantages of Irregular Packing:

Reduces pressure drop throughout the column.

Minimizes liquid holdup in the column.

Increases...

Read more →

In the production of ethanol, the use of spiral heat exchangers has found wide use. Spiral heat exchangers are divided into:

according to the method of arrangement-horizontal, vertical, inclined;

by design features-collapsible, welded (soldered);

according to the material of manufacture-structural steel, stainless...

Read more →

.jpg)

We offer a range of pumps for paint, glue, thick materials. .

The best technical solutions for pumping viscous products, reactive products or high viscosity food products.

We offer pneumatic pumps in different designs:

Housing

PP - polypropylene

AISI 316 - stainless steel

AL...

Read more →

.jpg)

Hydroponic systems are less forgiving than soil systems, and nutrient problems can quickly lead to various painful plant symptoms. For this reason, the composition of the nutrient solution and regular monitoring of the nutrient solution and the state of plant nutrients are crucial.

You can adjust the amount of nutrients with our hydroponic systems...

Read more →

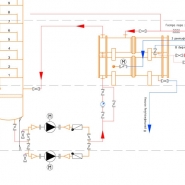

The use of heat recovery plays an important role in the technological processes of the alcohol industry.

The engineering company "BTS-Engineering" offers innovative solutions to reduce the consumption of process heat in

distilleries.

For example, a variant of the layout of equipment for "heating" the brew (distillation) columns (BC) with

alcohol-water vapors of the...

Read more →

The process of the distillery dreg processing

Distillery dreg contains about 6-9% of dry substances, depending on the quality of raw materials supplied to the technology. The raw protein, nitrogen-free extractives, fat, fiber, ash, vitamins and trace elements, included in the composition of grain raw materials passes in...

Read more →

Process of distillery dreg processing

Automation of technological processes is a labor-intensive process that requires highly qualified specialists, which in turn brings a rapid economic effect, expressed both in the quality of products and in the stable operation of the enterprise. Automation of technological processes allows you to control the...

Read more →

BTS Engineering Company together with engineers and technologists of the plant carried out a number of works on the design, manufacture and replacement of the brew column at the distillery with a capacity of 3000 dal per day. The economic effect of replacing the double-boiling column with a modern column designed by BTS Engineering engineers amounted to savings in energy consumption of...

Read more →

34 posts